One step ahead – with a KRONE BiG Pack. Whether you are making heavier, rock-hard bales with the BiG Pack HDP II or tying up to nine small bales neatly into one big bale with the MultiBale system, you’ll always be ahead of the field, using first-time innovations you won’t find anywhere else.

By buying a KRONE big baler you’re investing in experience and expertise in baler design. With so much experience under its belt, KRONE knows exactly what farmers need in the field and offers a complete range of balers with different chamber dimensions. The Variable Filling System, the unique MultiBale system and the camless EasyFlow pick-up with mechanical-drive rotor (Active Pick-up) are the stand-out features that have won international recognition and underpin the great success of the KRONE BiG Pack.

- HighSpeed: 20% higher throughputs while maintaining the same density

- HDP: Higher bale density – up to 25% heavier bales than from the BiG Pack 1290

- HDP II: Up to 70% higher throughput or up to 10% higher bale densities than from the HDP HighSpeed

- Chamber sizes from 80 x 70 cm to 120 x 130 cm

- VFS along with electronic baling pressure control for even bale densities

- X-Cut and VariCut cutting systems and PreChop for short cutting lengths

- Well-proven KRONE knotters for high-density and well-shaped bales

- MultiBale system packs up to nine small bales in one single big pack

- BaleCollect accumulator runs behind the baler collecting the finished bales as they leave the baler for greater harvest efficiencies and reduced field traffic

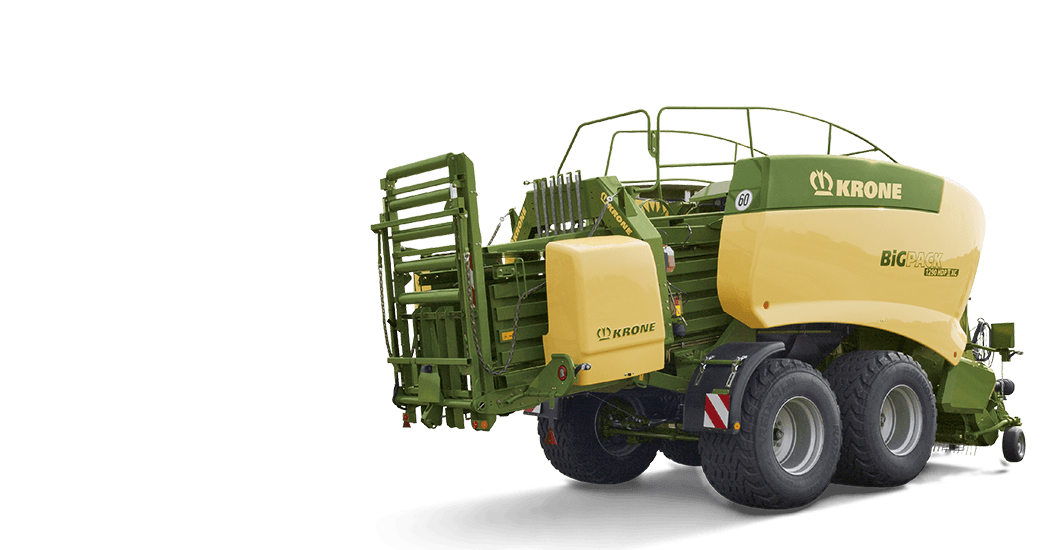

High-density large square baler

BiG Pack 1290 HDP II (XC)

Higher density – higher forward speeds. With its eight double knotters, this baler produces up to 70% higher throughputs or up to 10% higher densities than the BiG Pack HDP HighSpeed. It also delivers a lot more power on the field, making your straw logistics more efficient.

Product features

- Chamber sizes from 80 x 70 cm to 120 x 130 cm

- X-Cut and VariCut cutting systems and PreChop for short cutting lengths

- VFS along with electronic baling pressure control for even bale densities

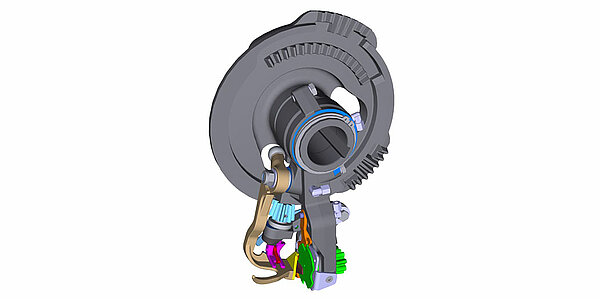

- New KRONE V-knotter system for highly compacted and dimensionally stable bales without snippets

- MultiBale system packs up to nine small bales in one single BiG Pack

- Up to 70% higher throughput or up to 10% higher bale densities than from the HDP HighSpeed

- Bale accumulator mounted directly on the rear of the baler for effective and soil-friendly bale collection

By buying a KRONE big baler you’re investing in experience and expertise in baler design. With so much experience under its belt, KRONE knows exactly what farmers need in the field and offers a complete range of balers with different chamber dimensions. The Variable Filling System, the unique MultiBale system and the camless EasyFlow pick-up with mechanical-drive rotor (Active Pick-up) are the stand-out features that have won international recognition and underpin the great success of the KRONE BiG Pack.

[Translate to EN (UK):] Höchste Einsatzsicherheit dank Doppelknotertechnologie ganz ohne lästigen Garnschnipsel. Der KRONE V-Knoter überzeugt.

High Performance: Delivering boosted productivity through higher operator comfort, the new BiG Pack generation is set to supplement the HighSpeed generation

2017: The KRONE BaleCollect is an effective tool in optimising straw harvesting. This bale collector can collect up to three bales in the field Thanks to its telescoping drawbar BaleCollect tracks behind the baler like trailer on public roads

2013: The BiG Pack HDP II rips up the record book. KRONE launches a completely new big baler that scales new heights in terms of throughput and density.

2011: Generation High-Speed overtakes the big baler market – with up to 20% more throughput than their predecessors while maintaining the same density.

2006: PreChop – The integrated pre-chopping system refines the straw harvest and opens up new opportunities for square bales.

2005: The BiG Pack 1290 HDP is launched and has had a significant impact on worldwide straw haulage ever since.

2003: KRONE presents the MultiBale system – the first baler on the market to tie big bales as well as up to nine small bales in one big pack.

1999: KRONE launches the VFS Variable Filling System. The double knotter is now available for many BiG Pack models.

1993: The BiG Pack is born – KRONE builds its first big baler ...

BiG Pack 4 x 4 (XC) HighSpeed: With a chamber height of 130 cm, you get fewer bales per hectare and save time and money on labour too – because the field is cleared fast. This baler is mainly used in straw and hay.

BiG Pack 1290 (XC) HighSpeed: These solid 1.20 m wide and 90 cm high bales are popular with farmers the world over. With its massive bale dimensions, this machine is mainly in demand for straw and hay, but it also handles silage successfully in some countries.

BiG Pack 1270 (XC/VC) MultiBale HighSpeed: This version enables you to pack up to nine small packs in one big bale. Big bales can be cleared quickly from the field, and the smaller packs are easy to distribute later on.

BiG Pack 1270 (XC/VC) HighSpeed: The 70 cm high x 120 cm wide chamber on this machine makes it truly versatile. Six single or double knotters produce firm and uniform bales in straw, hay and silage.

BiG Pack 890 (XC) HighSpeed: With four double knotters and a chamber measuring 80 cm in width and 90 cm in height, this machine has proved its worth time and again – not just in straw but also in heavy, wet silage.

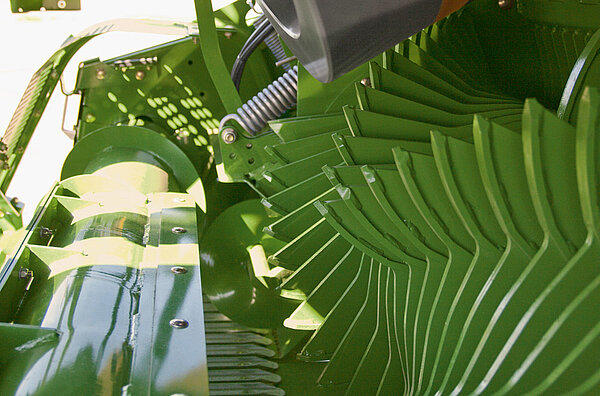

- Clean work: More power due to 30% higher speed compared to a controlled pick-up

- Powered feed roller: for superior performance even in brittle material

- Smoother running thanks to camless design

- Less wear with 68% fewer moving parts

- Maintenance-free and long-lasting

KRONE Active Pick-up – a clever combination of the tried-and-trusted camless EasyFlow Pick-up plus an additional powered feed roller. The speciality of this pick-up is the design of the galvanized scrapers, which ensure a continuous and smooth crop flow as the tines retract. EasyFlow can work 30% faster – allowing for faster forward speeds and higher throughputs.

- 16 blades or 26 blades provide 44 mm theoretical cutting length depending on channel width

- The tines have wide, hard-wearing Hardox plates

- The blade cassette lowers hydraulically and pulls out like drawer

- The blades are controlled in groups

- Lowest power requirement in the market

With a full set of blades, you can achieve theoretical cutting lengths of 44 mm. Wide Hardox supporting surfaces on the V-shaped paddle tines reduce the power requirement and ensure the best cutting quality, high throughput and long service life.

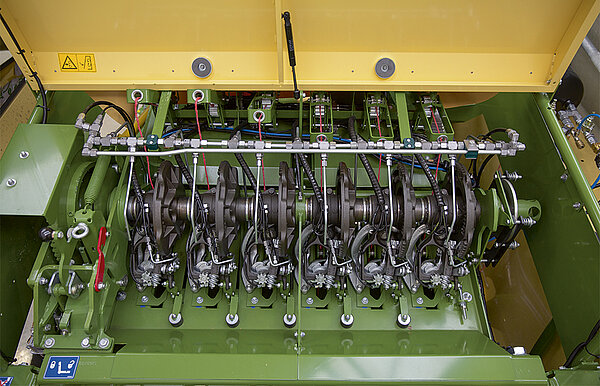

- Up to 51 blades

- Variable blade control system

- Belt drive and four-star rotor for maximum efficiency

- Produces top quality short straw

- Easy and convenient to maintain

- Extremely highly protected drive train for the highest throughputs on the market

The KRONE VariCut is an ultra-flexible multiple blade cutting system for the BiG Pack 1270 and BiG Pack 1290 HDP and comes with a choice of up to 51 blades. VariCut can produce short straw with a theoretical LOC of at least 22 mm – the ideal solution for animal feed or bedding.

[Translate to EN (UK):] Komfortable Montage und Wartung: Für Wartungsarbeiten kann die einteilige Messerkassette dank Schnellkupplersystem mit wenigen Handgriffen und mit Hilfe eines optionalen Transportgestells für einen Paletten-Hubwagen seitlich aus der Maschine herausgezogen werden.

A service aperture above the blades can be opened in a single action for removing deposits. The area around the blades and the individual blade protection system is kept clean with an integrated compressed air blower.

[Translate to EN (UK):] Variable Messergruppenschaltung: Die Messer können werkzeuglos in sechs Gruppen von 51, 26, 25, 12, 5 bzw. 0 Messern vorgewählt werden. Hydraulisch wird die vorgewählte Gruppe aus der Kabine heraus geschaltet. Alle Schaltnocken sind auf die Welle aufgesteckt und können zu individuellen Gruppen zusammengestellt werden.

[Translate to EN (UK):] Beim hydraulischen Zuschalten der Messer wird die Messerkassette im Rahmen verspannt. Die Laufrollen der Messerkassette werden dadurch entlastet und beim Schneiden entstehende Vibrationen sicher abgefangen. Dies gewährleistet eine dauerhafte Leichtgängigkeit beim Ein- und Ausziehen der Kassette.

[Translate to EN (UK):] Ein seitlicher Verbundriemen treibt Pick-up und Rotor an. Dank permanenter Schlupfüberwachung wird der Rotor bei Überlast automatisch abgeschaltet und die Messer aus dem Gutfluss herausgeschwenkt. Zum Wiederaufnehmen der Arbeit werden aus der Kabine zuerst der Rotor neu gestartet und dann die Messer eingeschwenkt.

- Short chop lengths – minimum 21 mm nominal lengths

- Adjustable LOC, two selectable counterblades

- Defibration effect for added liquid absorption

- Mechanical gearbox and hydraulic height control

PreChop is an integral front-mounted chopping unit on the KRONE big balers of the BiG Pack 1270 (XC/VC), 1290 (XC) und 1290 HDP (XC) series. It has 96 rotating blades and two rows of 47 counterblades that achieve a nominal LOC of 21 mm. But PreChop doesn’t only chop, it also visibly defibrates the stalks.

- Uniform densities courtesy of a multiphase feeding sequence

- Pre-compression in the feed chamber for maximum filling

- Stable bales even from small swaths

- Uniformly compressed bales for higher bale weights

- Automatic overload clutch for operating at full performance capacity

How the VFS system works: As the first step, the packer in combination with a feeder bar feed the material into the feed chamber where it is collected and pre-compressed. Once the feed chamber is filled to capacity, the feeder bar pushes the crop into the bale chamber. The VFS Variable Filling System from KRONE delivers rock-hard bales that keep their shape even in thin swaths and at slow forward speeds.

- High inertia and high speeds for a quiet running system

- Power is transmitted down clutch-protected drive shafts

- No shear pins in the drive train for maximum operator comfort

- Electronic baling pressure control for even bale densities

The on-board hydraulic system with automatic baling pressure control ensures firm bale shapes and tidy edges, even in wet conditions and in different crops. Two sensors measure the current force of the plunger. A control system compares this measurement with the operator settings and the on-board hydraulic system automatically adapts the pressure exerted on the chamber walls.

- Massive hydraulic rams for maximum bale densities

- An electronic star wheel sensor ensures uniform bale lengths

- Tandem axle up to max. 60 km/h or single axle up to 40 km/h

- A rigid or caster steer boogie axle

The KRONE BiG Packs have massive hydraulic rams for highest densities. Rigid or caster-steer 60 km/h tandem axles are available to boost productivity.

- Absolutely reliable – simple twine feeding system

- Cleaning by air

- Central lubrication provided as standard

- Long service life

The KRONE knotting system delivers a high-density and firm bale every single time. The double knotter technology on the BiG Pack 870 HDP is fitted as standard on all chambers measuring more than 70 cm in height, where it ties even high-density bales and crops that are prone to expanding into packs that hold. BiG Pack 1270 is fitted with single knotters as standard, but double knotters are available as an option.

[Translate to EN (UK):] Serienmäßig sind die BiG Pack 1270 mit Einfachknotern (System Deering) ausgestattet. Optional können aber auch Doppelknoter für die Maschinen geordert werden, die vor allem bei der Version Multibale zwingend notwendig sind.

[Translate to EN (UK):] Alle BiG Pack Modelle sind serienmäßig mit einer Zentralschmierung ausgestattet, welche sicherstellt, dass die wesentlichen Schmierstellen mit Fett versorgt werden. Lediglich einige wenige Schmierstellen müssen händisch versorgt werden. Erhöhter Verschleiß aufgrund von Mangelschmierung oder eindringendem Staub wird somit vermieden.

Small bales within a large bale

- Up to 9 single bales in one large bale

- Bale lengths as required: from 0.30 m to 1.35 m (1' to 4'5")

- Simple handling with small bales

- BiG performance in the field: Easy handling on the farm

- High-resolution colour touchscreens

- The control units on KRONE BiG Pack big balers are all ISOBUS-compatible.

- If the KRONE BiG Pack is hitched to an ISOBUS-compatible tractor, you can use the tractor terminal to control the baler.

Even the entry-level DS 500 from KRONE offers convenient and comprehensive control of all major functions from a colour touchscreen. The CCI 800 and CCI 1200 ISOBUS terminals take user comfort to the max, offering one screen that displays both the machine user interface and the images that are fed from camera.

- Up to 70% higher throughputs than the BiG Pack 1290 HDP HighSpeed

- or up to 10% higher density than the BiG Pack 1290 HDP HighSpeed

- Eight double knotters (KRONE V-knotters) for maximum baling densities without any snippets

- The twine boxes lower hydraulically for easy maintenance and refilling

- Machine cleaning KRONE PowerClean – as standard on the BiG Pack 1290 HDP II

Up to 70% higher throughput or up to 10% higher bale density than the BiG Pack 1290 HDP HighSpeed – these were the ambitious targets the KRONE engineers set themselves in designing the new BiG Pack HDP II. Many interesting features increase the efficiency of this baler and operator comfort.

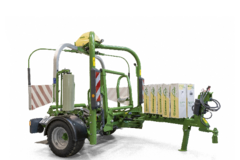

- Saves time and costs in big baling

- Telescoping drawbar for optimum rides

- Choice of various patterns of depositing the bales to suit multiple bale handling strategies

- Standard and integral weighing system

- Efficient and reduced soil compaction

Running behind the baler, the KRONE BaleCollect collects up to three square bales from a 120 cm wide chamber or up to five bales from an 80 cm chamber. And has a choice of unloading modes to prepare the bales for the next steps in the field, significantly shortening post-baling loading times, reducing journeys and minimizing soil compaction.

- Fully integrated moisture sensor in the baling chamber

- Fully integrated weighing system in the bale chute

- Camera system for safe reversing

- Extra twine boxes at the rear

For even greater convenience and effectiveness, choose from a number of options that add even more features to your machine, including moisture sensing and bale weighing systems that give accurate information on the job at hand, or LED work lights and reverse cameras for unobstructed vision and a clear all-round view.

Models

| BiG Pack 890 HighSpeed | BiG Pack 1270 HighSpeed | BiG Pack 1270 XC HighSpeed | BiG Pack 1290 HighSpeed | BiG Pack 1290 XC HighSpeed | BiG Pack 4 x 4 HighSpeed | BiG Pack 4 x 4 XC HighSpeed | BiG Pack 870 HDP HighSpeed | BiG Pack 870 HDP XC HighSpeed | BiG Pack 1290 HDP XC HighSpeed | BiG Pack 1290 HDP II | BiG Pack 1290 HDP II XC | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chamber width x height (cm) | 80 x 90 | 120 x 70 | 120 x 70 | 120 x 90 | 120 x 90 | 120 x 130 | 120 x 130 | 80 x 70 | 80 x 70 | 120 x 90 | 120 x 90 | 120 x 90 |

configure

|

| Bale length (m) | 1.00 - 2.70 | 1.00 - 2.70 | 1.00 - 2.70 | 1.00 - 2.70 | 1.00 - 2.70 | 1.00 - 3.20 | 1.00 - 3.20 | 0.50 - 2.70 | 0.50 - 2.70 | 1.00 - 3.20 | 1.00 - 3.20 | 1.00 - 3.20 |

configure

|

| No. of plunger strokes (per min.) | 49 | 45 | 45 | 45 | 45 | 38 | 38 | 49 | 49 | 45 | 45 | 45 |

configure

|

| No. of double knotters | 4 (Standard) | 6 (optional) | 6 (optional) | 6 (Standard) | 6 (Standard) | 6 (Standard) | 6 (Standard) | 5 (Standard) | 5 (Standard) | 6 (Standard) | 8 (Standard) | 8 (Standard) |

configure

|

| MultiBale | - | optional | optional | - | - | - | - | Standard | Standard | - | - | - |

configure

|

| Power requirement (kW/hp) | 80 / 109 | 85 / 116 | 100 / 136 | 90 / 122 | 105 / 143 | 130 / 177 | 145 / 197 | 105 / 143 | 120 / 163 | 145 / 197 | 170 / 231 | 190 / 258 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/4/csm_VariPack_Freisteller_f4bfc269dd.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)