Smart Implements: Everything is Controlled Automatically

The attachment devices of the autonomous towing machines (VTE) of KRONE and Lemken are automatically readjusted by means of high-quality sensor systems to ensure that optimum working quality is always achieved.

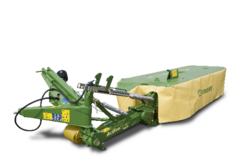

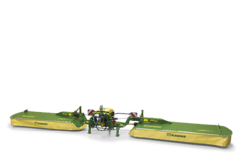

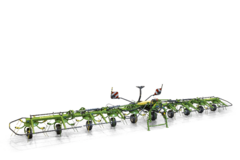

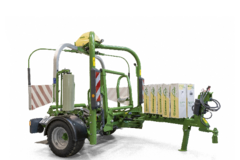

Spelle and Alpen, September 2023: The process unit (VTE) of KRONE and Lemken presented under the name "Combined Powers" combines an autonomous towing machine and various "intelligent attachment devices", the Smart Implements, for farming and green forage harvesting. The standard machines are equipped with high-quality sensor technology that enables safe autonomous work on the field while at the same time ensuring an optimum work result.

A standardised interface connects the towing vehicle with the attachment device and ensures continuous data exchange in real time. In this manner the data recorded on the attachment device and forwarded to the towing vehicle is continuously compared with previously defined values. In case of deviations, changes are made automatically to the setting of the attachment device. In extreme cases of malfunctions or damage, the unit is stopped.

Relief from Field Work

The technology of Smart Implements is the basis for automated driverless operation of the VTE. They are also very useful in combination with conventional tractors, since they perform monitoring and control tasks semi-automatically that the driver would otherwise be responsible for. Overloading of the drive train can be prevented by comparing different sensor values within the Smart Implements. Utilisation is used as a control variable for operating the attachment device at the optimum operating point. For green forage harvesting, for example, the sensors on the mower detect too high a load on the sward and communicate this to the towing vehicle. It converts the information into a "lift command" and adjusts the mowers for optimum relief. The depth control is readjusted as required for cultivating if there are changes to the ground conditions or the proportion of organic mass.

Damage and wear to working tools cannot be avoided. A Smart Implement detects these by means of process and disturbance variables very quickly compared to human perception and this makes it possible to reduce downtimes considerably by correcting deficiencies at an early stage.

During the work process, a digital workbook is created for reference. In this way, information from the VTE including the coordinates of obstructions such as power lines or the location of lost mechanical components can be saved with the exact location.

Press Contact:

Markus Steinwendner

Head of Marketing KRONE Agriculture

+49 5977 935 188 20

markus.steinwendner@krone.de

www.krone-agriculture.com

Marie Ehses

Marketing LEMKEN GmbH & Co. KG

+49 2802 81 250

m.ehses@lemken.com

www.lemken.com

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN (US):] Testname](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)