30 years BiG Impact

The launch of the KRONE BiG Pack onto the large square baler market in the year 1993 marked the start of an era that brought a significant reduction of the workload of contractors and farmers.

To this day, the BiG Pack machines have been upgraded with variety of sophisticated innovations which define the standard for the machine and bale quality of large square balers.

The changing climatic conditions and the associated challenges in practical application require robust and precise machines that can work efficiently in any type of conditions world-wide.

Whether you are faced with hot or cold, humid or dry, dusty or dirty conditions – KRONE develops practical solutions and ideas that impress!

Over the past 30 years, BiG Pack customers around the world have benefited from this development. Under the name "BiG Impact", read these customers’ stories and learn why they go for KRONE BiG Pack to make their workdays easier.

Quality

BiG Pack – a synonym for quality

Since 1993, BiG Pack has been a synonym for quality! We have always been true to the quality claim “Made in Germany”. Herbert Ruge, one of the first customers to buy a KRONE large square baler, has produced more than 330,000 square bales of silage and straw over a period of 16 years. Since then, two facts have not changed: Mr Ruge still relies on the BiG Pack for his work, and we from KRONE always kept abreast of development to offer the best possible machine quality at all times. Also the bales produced on our large square balers are in keeping with this quality level.

VariCut / PreChop: The perfect cut

With the VariCut cutting unit, the efficient production of short straw is easy. Those who prefer a minimum cutting length of 44 mm will be perfectly satisfied with the variant with 26 blades. The 51-blades-variant is the unit of choice for those who want straw of half this length. In both cutting unit variants, the selectable, hydraulically actuated blade group control system allows you to vary the cutting length according to your requirements. The PreChop front-mounted pre-chopper is available for chopped material of even shorter length. With 96 rotating blades and counterblades, this unit chops the crops even smaller while fraying them as well. This gives you extremely absorbent, low-dust straw that makes not only perfect bedding but also good forage.

Density

Almost as tight as a diamond!

Almost as tight as a diamond! Driving a BiG Pack, the farmer can expect to receive premium-quality, extremely tight bales, resulting in top-quality forage, healthy animals and good milk. This density also helps you to save costs: high-density bales significantly reduce the transport and storage costs. This advantage is particularly important in regions where bales are moved over long distances.

Extended bale channel: Further improvement of bale shape and density

The new BiG Pack machines are equipped with a 20% longer bale channel and have top baling flaps over the entire channel width. These are perfect conditions for even better bale shape and density, beneficial particularly with dry crops and high throughputs. Even with changing moisture conditions and different crops, all the bales will be of the same shape and have perfectly defined sharp edges. This is ensured by the on-board hydraulic system with the automatic baling pressure regulation. The BiGPack is equipped with a divisible residual bale ejector which provides additional convenience and saves time when changing fields. It can be used to either eject the last bale, or empty out the channel completely.

Capacity and Throughput

Rock-hard premium-quality square bales

Haste makes waste? Not when it comes to the rock-hard premium-quality square bales of the BiG Pack. Their high speed on the field saves you not only time but money as well. Particularly the HighSpeed models of the BiG Pack are designed for fast working on the field. Working at full speed, independently of the working conditions on site, while producing bales of constantly high quality – this is a unique KRONE feature!

Active Pick-up

KRONE “Active Pick-up” – a clever combination of the tried-and-trusted camless EasyFlow Pick-up plus an additional powered feed roller. The special feature of this pick-up is the design of the galvanised scrapers. They are shaped to ensure a continuous crop flow at tine immersion. 30% higher rotational speed increases the advancing speed by 2 km/h, with the other conditions remaining unchanged. Speed starts already at pick-up!

VF system: Optimum efficiency

With the Variable Fill System (VFS), you work with maximum efficiency no matter what crops type, swath size and swath shape. In particular with short material, the VFS ensures optimum mixture and pre-compaction compression for optimum filling of the bale channel. This in turn provides maximum throughput with optimum utilisation of the machine. Even drivers who are new to the job can work very efficiently with the VFS since they set the desired pre-compaction compression at the operating terminal and can constantly monitor the machine efficiency. All components of the VFS are extremely robust, ensuring a long service life.

Innovation

The next big thing.

The next big thing. Innovation with the customers, for the customers. From the start, KRONE’s further development of the BiG Pack has been guided by the customers’ requirements. To this day, these focus in particular on basic needs such as time and cost savings, e.g. in connection with transport and storage costs. The development of the BiG Pack High Density Press (HDP) for rock-hard bales was an important milestone in this respect.

High Density Press: The superlative in terms of efficiency

When it comes to large square balers, the BiG Pack 1290 HDP sets standards. Accounting for by far the largest proportion of the large square balers built each year, this model produces extremely compacted bales in 120 x 90 cm format. With a bale weight of 500 kg for straw bales, the BiG Pack HDP yields an approx. 25% greater bale density compared to conventional large square balers, resulting in a corresponding reduction of follow-up costs. These fall in particular to savings in respect of labour and logistics costs resulting from enhanced efficiency in straw collection, unloading of the transport vehicles and utilisation of storage capacities. This more than compensates for the additional costs of components adapted to the high performance and susceptibility to wear of the machine. In case of the BiG Pack HDP, competence pays off!

V-knotter: Guarantee for stability and safety

With the new V-knotter, KRONE launched a game changer: This double knotter combines the high knot stability of the loop knot of the single knotter from McCormick with the significantly higher operational reliability of the double knotter from Deering. In particular with the high baling density of the BiG Pack large square balers, these benefits really make a difference. This is attributable to a leading-edge innovation: The V-knotter pulls the twine ends remaining in case of the conventional double knotter from Deering into the second knot in the shape of a loop, which significantly improves the stability. By means of the V-shaped billhook with the central opening, the loop can be pulled off easily. In addition to increasing the stability, the V-knotter also avoids environmental pollution from twine ends on the field.

Comfort

BiG Impact also for BiG Pack drivers!

BiG Impact also for BiG Pack drivers! When developing the BiG Pack, making the operation and functionality of the machine as comfortable as possible has been a design priority from the start. Extremely easy access thanks to hydraulically opening and folding side hoods is just one example for the large range of functions that can be controlled directly from the tractor cabin. From now on, the driver can remain in the tractor seat when changing fields. Also the daily maintenance is reduced to a minimum. Thanks to KRONE PowerClean, depositions between the knotters or on the bale channel are history.

For even more convenient straw collection, use the optional KRONE bale accumulator BaleCollect that can deposit several bales at the same time – on request even with GPS control!

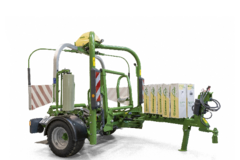

BaleCollect: Reduced journeys for bale collection

Efficient collection of big bales with minimum soil compaction – no problem with the BaleCollect bale accumulator running directly behind the BiG Pack: The KRONE BaleCollect collects up to three square bales from a 120 cm wide chamber or optionally up to five bales from an 80 cm chamber. Then, choose between various unloading modes to prepare the bales for the next steps in the field. Optionally, they can even be deposited in up to five A-B lines by means of a GPS-controlled system. This significantly shortens post-baling loading times, reduces journeys and minimises soil compaction.

Innovative folding concept: Easy maintenance under the hood

Regular maintenance increases machine reliability and lifetime. To provide optimum access to the machine components for maintenance, the side hoods of the BiG Pack can easily be folded in and out at the push of a button from the driver’s seat, or directly at the machine. This ensures convenient working at eye level. The same goes for the twine boxes integrated in the side hoods: They can be folded down hydraulically for spool of twine treplacement. Thanks to automatically controlled LED floodlights, all maintenance work can easily done at night time.

Optimum operator comfort: Control via terminals with touch displays

Also the standard KRONE DS 500 terminal allows you to operate all major machine functions via a colour touch screen display. The ISOBUS terminals CCI 800 and CCI 1200 with their 8” and 12” colour displays offer even greater operator comfort thanks to their dual use as machine control unit and camera monitor. This multi-function system is not only a cost-efficient solution but also offers best possible all round view, allowing the operators full focus on their work without any distraction. As an alternative to the KRONE terminals, you can also operate the machine via the ISOBUS-capable tractor terminal.

Reliability

Many terrains, one machine. Farmers world-wide operating under a wide range of agricultural conditions opt for the BiG Pack. Reliability and high quality of the work results cannot be left to chance. Constantly changing natural conditions pose challenges for agricultural machinery, and every machine standstill means a loss of time and money. This is why KRONE not only commits to premium quality in the production of the BiG Pack, but also offers reliable supply of parts and excellent service that you can trust on at any time.

KRONE PowerClean: Prevents material from collecting

A directed air flow blows dirt particles off before they can deposit on the BiG Pack. This is achieved by means of two turbines that maintain a high air pressure inside the knotter bay, blowing air over the knotter table and guiding it down to the axle behind the twine boxes. In this way, the KRONE PowerClean ensures that large areas of the large square baler remain clean. This not only improves the operational reliability of the machine in the field but also its safety on the road.

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN (US):] Testname](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)