RX and ZX forage wagons – maximum transport volumes and perfect cuts

Featuring the new OptiGrass cutting system and maximum throughputs, the RX and ZX forage wagons from KRONE set new benchmarks for professional forage trailers.

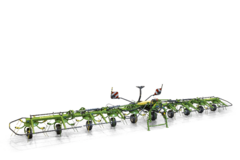

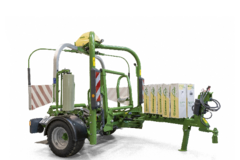

Spelle, June 2023. Restyled and technically rearmoured, the new KRONE RX and ZX dual-purpose forage wagons set new standards in the professional high-capacity forage wagon sector. The top model range is the ZX with capacities of 43-56m3 whereas the smaller RX ranges comes in 33-40m3 volumes, both cutting the incoming material to shortest lengths and producing feeds of unprecedented quality. At the heart of this technology is the new ‘OptiGrass 28 und 37’ cutting system which produces absolutely clean and precise cuts for an optimal and consistent structure from the first to the last blade of grass.

Integral rotor with SplitCut

The grass is gathered and fed to the rotor cutter by the 2.12m wide and camless EasyFlow pick-up. Its hydraulic drive allows operators to adjust the tine speed to current throughputs for a uniform and consistent flow to the rotor cutter, which translates into an excellent feed quality and better fuel economy. The pivoting and electro-hydraulically suspended EasyFlow pick-up unit suggests effective ground hugging and an optimum performance even in difficult harvest conditions.

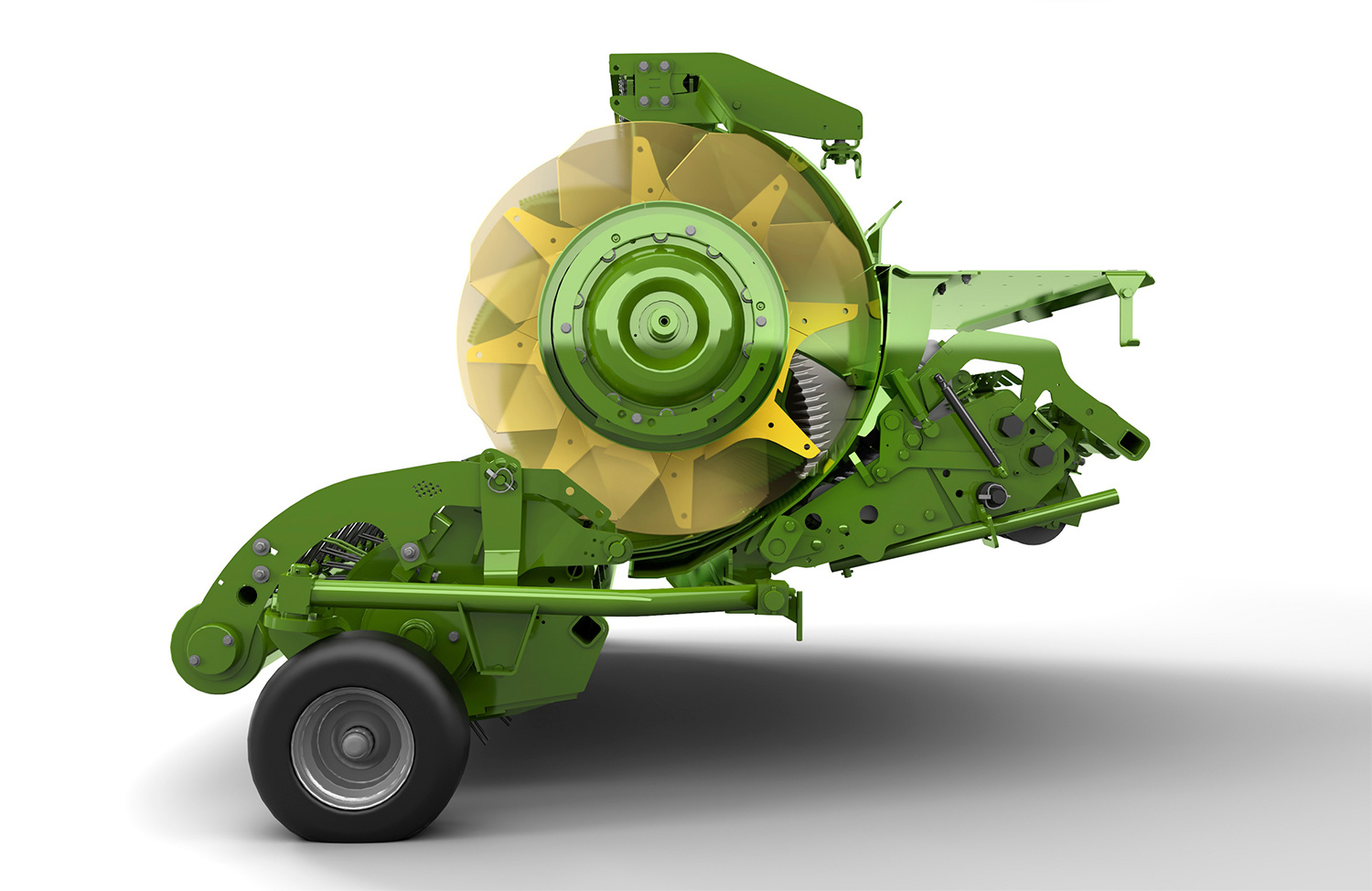

Central to the new RX and ZX models is the cutting system with integral rotor that distributes the crop uniformly across the full cutting width. Measuring 88cm in diameter, this rotor develops an enormous appetite that suits the capacities of these forage harvesting pros. The knife blades on the rotor cutter are arranged on the sides of the feeding plates, making perfect scissor-like cuts without squeezing the forage, an input-power efficient technique that is also gentle on the crop. Depending on the size of the cutting system, the feed plates are 17mm or 22mm wide and all are made from high-tensile steel for heavy-duty and long-lasting performance. The incoming material is reliably fed to the middle of the rotor by 22cm long augers out on the ends of the integral rotor. This combines with the KRONE SplitCut system to ensure not a single grass blade enters the wagon uncut – not even those flowing over the ends of the rotor. SplitCut splits the crop flow on the outboard knife blade and feed tines reverse the flow upon which it is guided to the middle of the rotor by deflector plates for cutting. It is this design that translates into exact cuts across the full working width.

OptiGrass for finest cuts

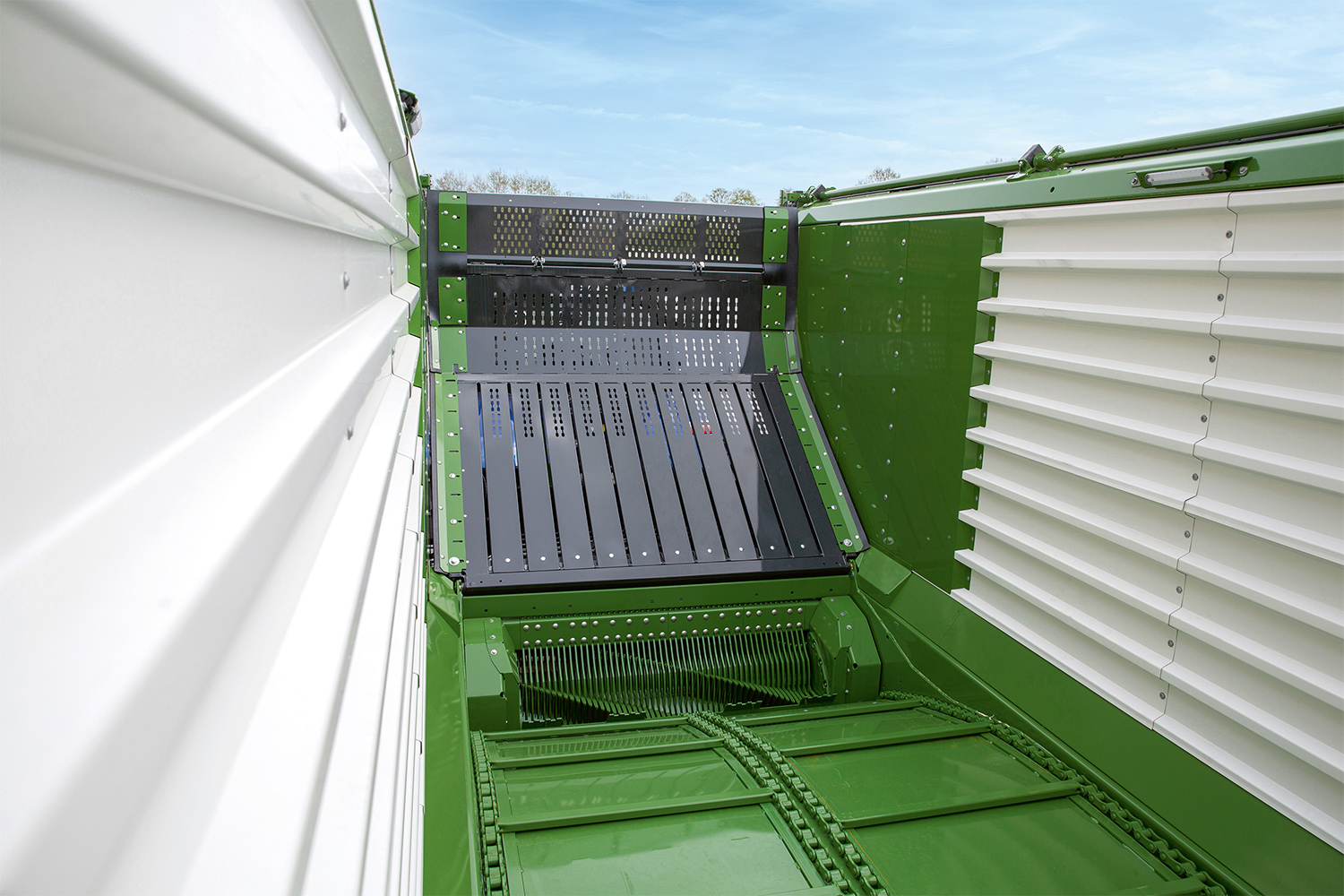

The new high-capacity cutting system is available in two versions – the ‘OptiGrass 37’ with 40 blades and nominal cuts of up to 37mm and the ‘OptiGrass 28’ with 54 blades for a nominal chopping length of up to 28mm, which is the ideal length for wet silage. In addition, the OptiGrass cutting system with its scissor-like precision cuts not only makes perfect cuts but also offers an unprecidented level of operator comfort. For example, potential blockages are removed by dropping the blade cassette hydraulically and then raising it again after the blockage is removed. The blade cassette also pulls out to the left side for convenient replacement of the individually overload protected blades. Then all blades are released from a central lever and replaced without the need of tools. We recommend opting for the KRONE SpeedSharp knife sharpener. Its grinding discs sharpen all 40 or 54 blades also in the field and within five minutes, carrying out two or three grinding cycles. Each time the grinding disc is applied at a perfect angle for a consistent contact pressure and perfect grind for premium-quality forage.

The perfect driveline

The wide rotor is powered by an in-board planetary gearbox and a PowerBelt for maximum throughputs. This PowerBelt on the RX transmits about 25% higher pto rpms compared with the predecessor; on the ZX, the pto power flow increased by up to 10%. Absorbing peak power demands, this type of driveline stands for very quiet running and hard wearing. The driveline is protected by a clutch that absorbs 2500Nm on the RX and 3000Nm on the ZX. This intelligent design initially provides a higher power take-off and then reduces it in the planetary gearbox – a torque-reducing technology that helps reduce component wear. As another unique KRONE feature, the two pulleys are swapped easily and quickly for convenient speed adjustment to conditions. High-yielding crops and voluminous swaths are processed at rotor speeds of 47rpm (ZX) and 43rpm (RX) and low-yielding crops and small swaths at 40rpm and 36rpm. This way, the space behind the rotor is filled to capacity for high pre-compression and the best possible cutting quality. At the same time, it allows the wagon to adapt to varying harvest conditions also behind a smaller tractor.

The floor on both the ZX and the RX slopes towards the rotor for easier filling and less tractor power. At the same time, the design leads to a higher level of compression inside the heap for maximum filling volumes. For adaptation to varying harvest conditions and dry matter contents, the operator can control the level of pre-compression and cutting quality by pivoting the hydraulic headboard from the tractor cab. The headboard has the standard PowerLoad system which makes the loading process easier and more efficient. The system consists of sensors that constantly measure the pressure that is exerted on the headboard plus the filling level and helps control the chain-and-slat floor, advancing it in one of three different speeds relative to the dry matter content of the crop. This way, the crop is compressed at a consistent pressure for maximized fills.

All RX and ZX models are available either with discharge rollers (GD) or without these (GL). The GD models have three standard discharge rollers that measure 470mm in diameter and have their tines arranged in chevron style for a uniform distribution of the material onto the clamp. The rollers are driven by a robust right-angle gearbox and 1” roller chains with automatic chain tensioners.

Great ride comfort in any terrain

Gentle is the buzzword not only for feed treatment but also for treading on the turf. The RX and ZX models run on tandem or tridem axles that distribute the weight uniformly to all wheels. Especially the axles that have hydraulic pressure compensation are ideal in undulating terrain and on slopes. Various types of arable, grassland or transport tyres are available with up to 30.5” tread profiles to suit various applications.

Another boon for good ride comfort expecially on roads is the new articulated drawbar with hydraulic height control and standard suspension. Slim and compact, the bar makes for excellent operator visibility of the pick-up and enhanced manoeuvrability. In combination with the intelligent caster-steer axle and the optional and contact-less electronic forced steering system, the sward is protected and the tyre wear is minimised.

Large choice of options

Various options such as crop covers, a weighing system and the integral silage additive applicator with a 200l tank and four flat fan nozzles on the pick-up or rotor cutter are available for bringing the KRONE RX and ZX wagons to an absolutely all-round and professional level. Another recommendable feature is the new electronic filling level sensor which is standard specification. This measures the filling level by measuring the advance of the chain-and-slat floor and displaying the reading on the terminal on a scale from 0 to 100.

All machines come with a software that allows operators to customize the lubrication intervals for the central lubricator. On top of this, there is a standard Premium LED lighting kit which lights the vicinity, the crop flow system, the load space and the lubrication points. As for control units, the ZX and RX models are available with a variety of control units, ranging from the DS 100 head unit to the premium-level ISOBUS CCI 800 and 1200 terminals that provide intuitive user interfaces and visualize the machine functions.

Summary: By presenting the updated RX and ZX models, KRONE once again underscores its leading position in the forage wagon market. At the heart of the new developments is the new OptiGrass cutting system that combines with further technical refinements for creating feeds of the highest quality – at maximum efficiency and reliability as demanded by professional customers.

Press contact

Markus Steinwendner

Head of Marketing KRONE Agriculture

+49 5977 935 188 20

markus.steinwendner@krone.de

www.krone.de

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)