KRONE Digital

Maschinenbedienung und Datenmanagement

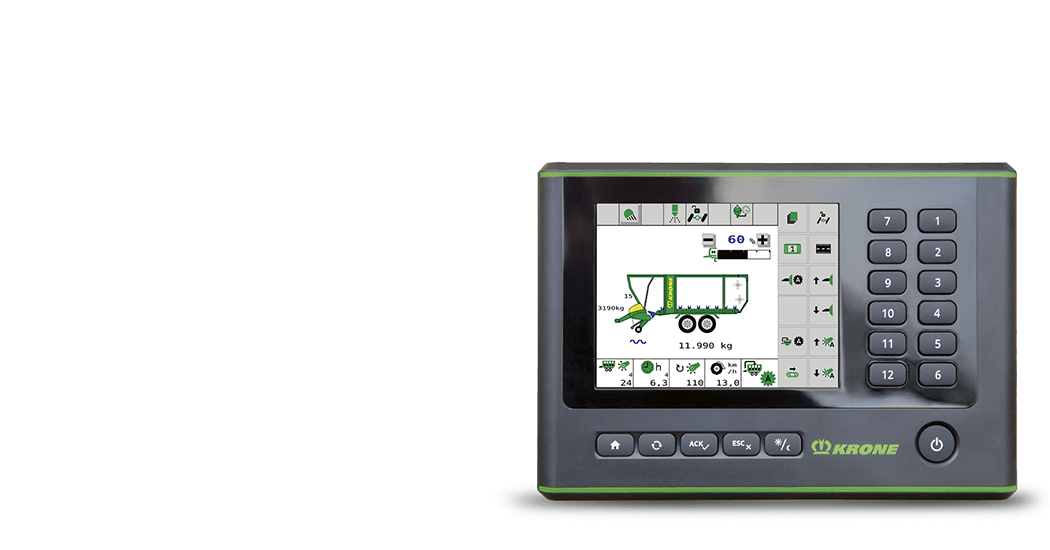

- Machine terminals with intuitive user interfaces optimized to KRONE machines

- Optional AUX joystick and cameras

- SectionControl for convenient mowing and swathing

- TIM tractor implement management

- KRONE Smart Telematics – a bird’s-eye view of the fleet and fleet data analysis

- agrirouter – data communication across ‘borders’ and down the value chain

- NEXT Machine Management data evaluation

More time for the important things

KRONE Digital

Product Features

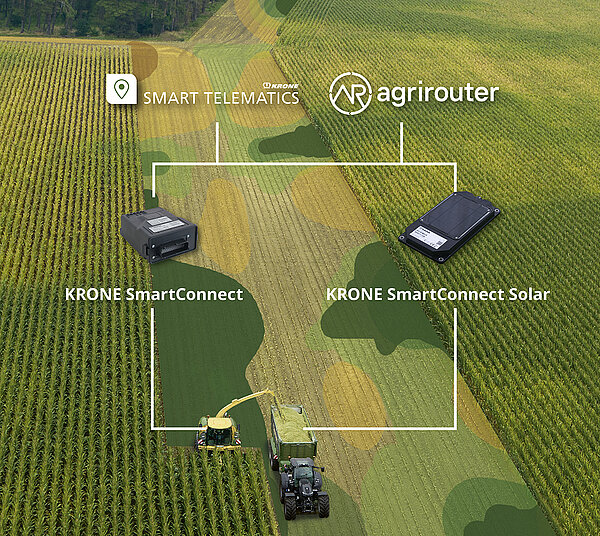

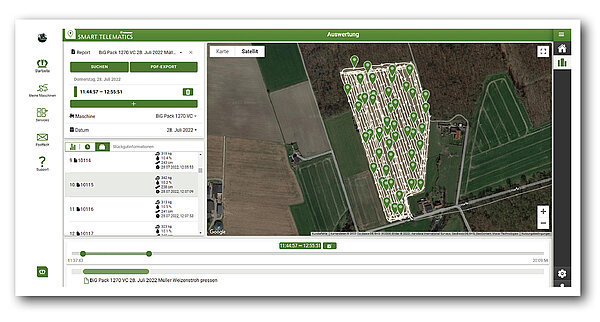

When it comes to data management, KRONE offers you various solutions tailored to your needs. This includes automatic real-time data acquisition using the SmartConnect Solar and SmartConnect telemetry units. KRONE Smart Telematics puts live machine data at your fingertips. As the machine data is stored, the historical performance of the machines can also be displayed and analysed. In addition, the data can be sent directly to a farm management system via the universal data hub agrirouter.

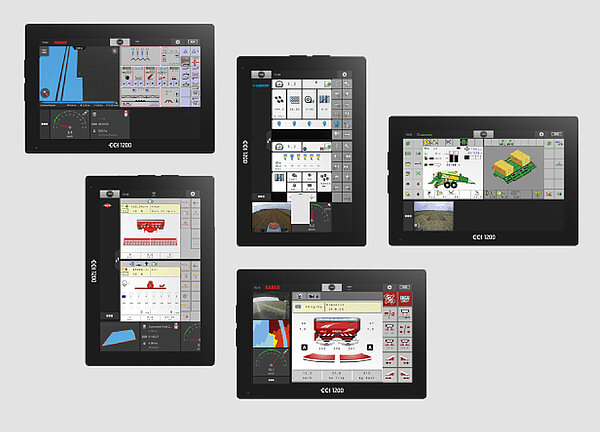

KRONE offers an optimal solution for operating your KRONE machine. From entry-level control units to ISOBUS-compatible terminals to suit every application.

The CCI.Control app enables data management directly on your CCI terminal. This allows you to create or import jobs, start, stop and then export them via a USB interface. In addition, the CCI terminals can be connected wirelessly to the agrirouter in conjunction with the standard WLAN receiver.

With its 12" widescreen display, the CCI 1200 offers plenty of space for displaying several applications simultaneously. Nevertheless, it can be mounted compactly in the cabin. The incredible display and flexible layout of machines, camera and Section Control make the whole season enjoyable.

With its 12" widescreen display, the CCI 1200 offers plenty of space for displaying several applications simultaneously. Nevertheless, it can be mounted compactly in the cabin. The incredible display and flexible layout of machines, camera and Section Control make the whole season enjoyable.

Les différentes fonctions de la machine portée sont configurées sur la manette CCI A3 au moyen d'un terminal. Les dernières affectations enregistrées sont toujours de nouveau appelées en cas de changement d'outil porté. En association avec les terminaux CCI 800 et 1200, il est en outre également possible d'affecter à la manette AUX CCI A3 des fonctions du terminal, par exemple activer/désactiver Section Control. Ainsi le conducteur peut tout gérer avec une seule manette.

On the BiG M and BiG X self-propelled machines, the camera images are integrated into the operating terminal. When reversing, the terminal automatically shows the image on the terminal. With the BiG X, a camera can also be mounted on the spout.

A DLG-certified camera system is available as an option for all EasyCut F front mounted mowers without an A-frame. The system is DLG certified and offers two views on the same screen for improved visibility in awkward situations. For example, narrow field gates are now easily managed without a helper. The package comprises two cameras, the display screen and the necessary wiring.

On the BiG M and BiG X self-propelled machines, the camera images are integrated into the operating terminal. When reversing, the terminal automatically shows the image on the terminal. With the BiG X, a camera can also be mounted on the spout.

On KRONE rakes and triple mowers, the partial widths can be switched via all ISOBUS terminals with Section Control. The control of the partial widths on the BiG M is taken over by the CCI 800 or CCI 1200 ISOBUS terminals with Section Control licence.

The EasyCut B 880 CV/CR Collect, B 950 Collect, B 1000 CV/CR (Collect) and B 1050 CV (Collect) mowers are available in conjunction with ISOBUS electronics with Section Control. All partial widths automatically switch between headland and working position at the optimum time reducing operator strain and maximizing productivity.

Thanks to Section Control, the individual rotors on the Swadro TC 1370, TC 1570 and TC 2000 are automatically controlled between working and headland positions. With the rakes it is possible to install the optional GNSS receiver directly on the frame. This means that tractors without their own GNSS receiver can also use the Section Control function on the rake.

With the aid of Section Control, the individual mower units on the BiG M are automatically raised at the headland and lowered back into the working position. In this way, multiple processing of the mown crop is avoided to the benefit of forage quality and the driver's workload is once again significantly reduced.

Thanks to the automatic sequence of the baling process, the machine works continuously with optimum throughput. This reduces fuel consumption and costs per bale.

Thanks to the automatic sequence of the baling process, TIM gives you uniform and consistently dense bales.

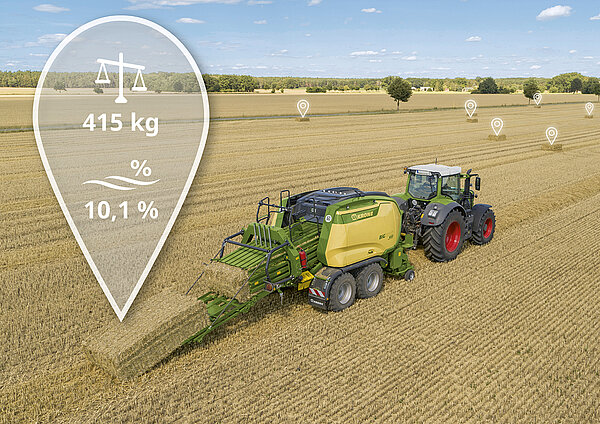

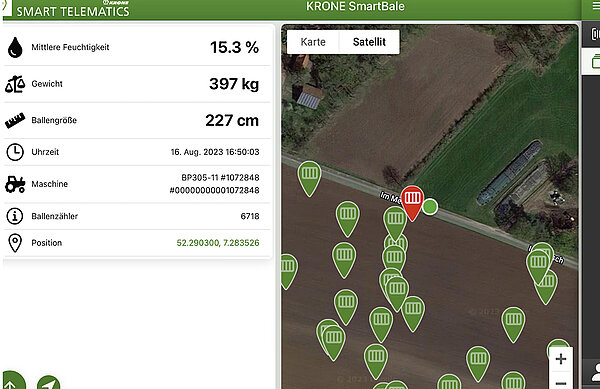

On the KRONE Comprima round balers, the bale weights can be determined via four weighing pins in the wrapping table. The bale weights are displayed directly on the terminal. In addition, further data such as moisture, bale size and position are recorded for each individual bale.

On the KRONE BiG Packs the bale chute and the KRONE BaleCollect can be equipped with an integrated scale. The bale weights are displayed directly on the terminal. In addition, further data such as moisture, bale length and position are recorded for each individual bale.

On the KRONE loading and forage transport wagons, the electronic weighing device is measured via gauging pins on the drawbar as well as on the tandem or tridem unit with hydraulic compensation. The weight of the load is equivalent to the accumulated drawbar tongue load and axle load. The weight is recorded and evaluated by job and displayed on the display screen.

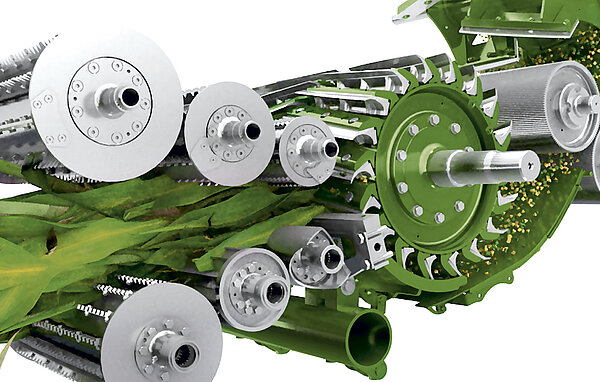

The CropControl yield metering feature on the KRONE BiG X computes the yield by measuring the crop flow. The crop flow is measured by using the speed and the distance between the two leading pre-compression rollers. Thanks to the six pre-compression rollers and regular calibration, the yield recording always works accurately, even under changing harvesting conditions.

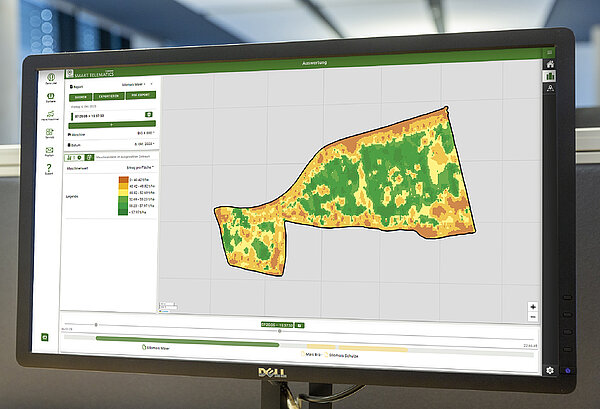

The machine data is visualised in the evaluation. The yield mapping of the forage harvester reveals the potential of the field and at the same time is used to check the success of the agronomic measures. The bale map enables the dispatcher to plan the collection logistics perfectly, as the locations and information of the bales can be viewed. In addition, this data can be made available to the customer transparently in an individual PDF report.

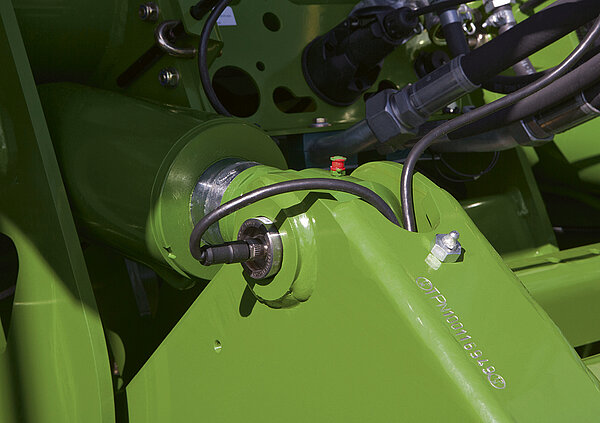

The KRONE SmartConnect telemetry unit integrated into the machine's BUS system automatically transmits the machine data to KRONE Smart Telematics. With the aid of the autonomous KRONE SmartConnect Solar telemetry unit, machines without their own electronics or rental machines can also be connected to Smart Telematics, regardless of the manufacturer.

Farming 4.0 with KRONE When it comes to data management, KRONE offers you various solutions tailored to your needs. These include the KRONE SmartTelematics machine monitoring system and the universal data management platform agrirouter to which you connect via KRONE SmartConnect and SmartConnect Solar – our telemetrics units. Data are evaluated by a farm management software of your choice, e.g. AgForce. You can also download software applications and flexibly book extra engine output on demand and in real-time via the E-Solutions shop.

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)