NEW: KRONE BiG Pack HDP II 1290 (VC) – Equipped with eight revolutionary and snippet-free KRONE V-knotters, this is a professional machine offering maximum bale density, unmatched power and uncompromised efficiency even in the most difficult operating conditions. The BiG Pack HDP II 1290 (VC) sets new standards producing an extremely high number of bales and exceptional bale density in the shortest amount of time. Sturdy and designed for a long service life, it tackles the harshest conditions with ease, every day and in every season. This machine is the perfect solution for anyone looking for uncompromised power.

- Maximum throughput at highest baling density – the most powerful machine of the range

- Powerful starter aid simplifying machine start-up even further

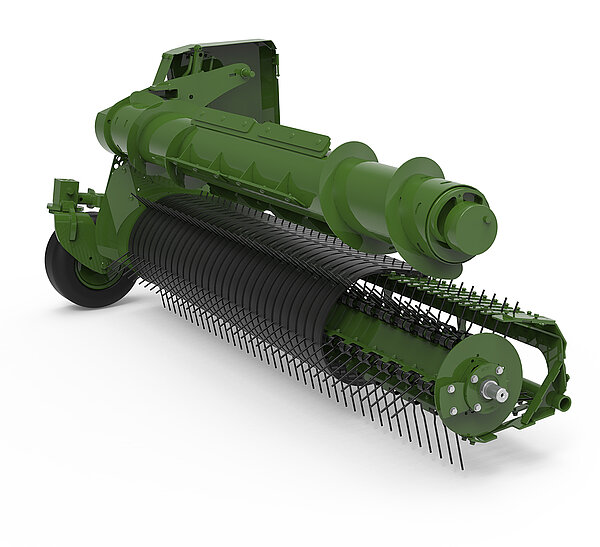

- Proven Active pick-up for the highest throughput and minimal wear – now includes hydraulically adjustable crop press roller unit

- VariCut cutting unit with 26 or 51 blades and belt drive – for maximum power and the best cutting quality

- Variable Filling System (VFS) – electronically adjustable from the cabin, ensuring thorough mixing and even channel filling

- Eight snippet-free double knotters (KRONE V knotter) guarantee maximum operational safety

- KRONE PowerClean system uses positive pressure to keep the knotter table clean – impurities never develop in the first place

- New maintenance concept – significantly simpler offering optimum accessibility

- Large tyres (26.5" or 30.5") ensuring sward protection during operation and minimal rolling resistance

- Ready for the dosing system tagger and BaleCollect as standard

BiG Pack HDP II is Farm Machine 2026

The large square baler KRONE BiG Pack HDP II 1290 (VC) takes 1st place and wins the FARM MACHINE 2026 award in the forage harvesting category.

FARM MACHINE, formerly known as 'Machine of the Year', has been awarded since 1997.

FARM MACHINE 2026: More information about the award can be found here.

The new BiG Pack HDP II

A baler in a class of its own

With the new BiG Pack HDP II 1290 (VC), KRONE is redefining the standards of professional straw baling. Developed to meet the highest demands in agriculture, it combines maximum baling density, enormous throughputs and intelligent technology with maximum operator comfort, ease of maintenance and durability. The machine achieves an extremely high density, especially when working with dry straw, so that transport and storage capacities can be utilised optimally. Recognisable from the outside by its new, sleek design, the KRONE engineers have developed the technology of the HDP II 1290 and are now presenting an even more powerful successor to this successful model.

Read the news

New:

VC variant with 51 blades

The VariCut 51 system allows operators to select the blades in sets of 51, 26, 25, 12, 5 and the VariCut 26 offers sets of 26, 14, 12, 6, 6 blades. The preselected group is engaged hydraulically from the cab. All actuating cams are attached to the shaft and can be combined to form individual groups.

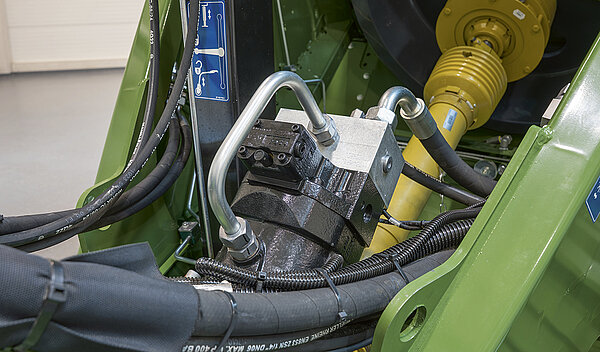

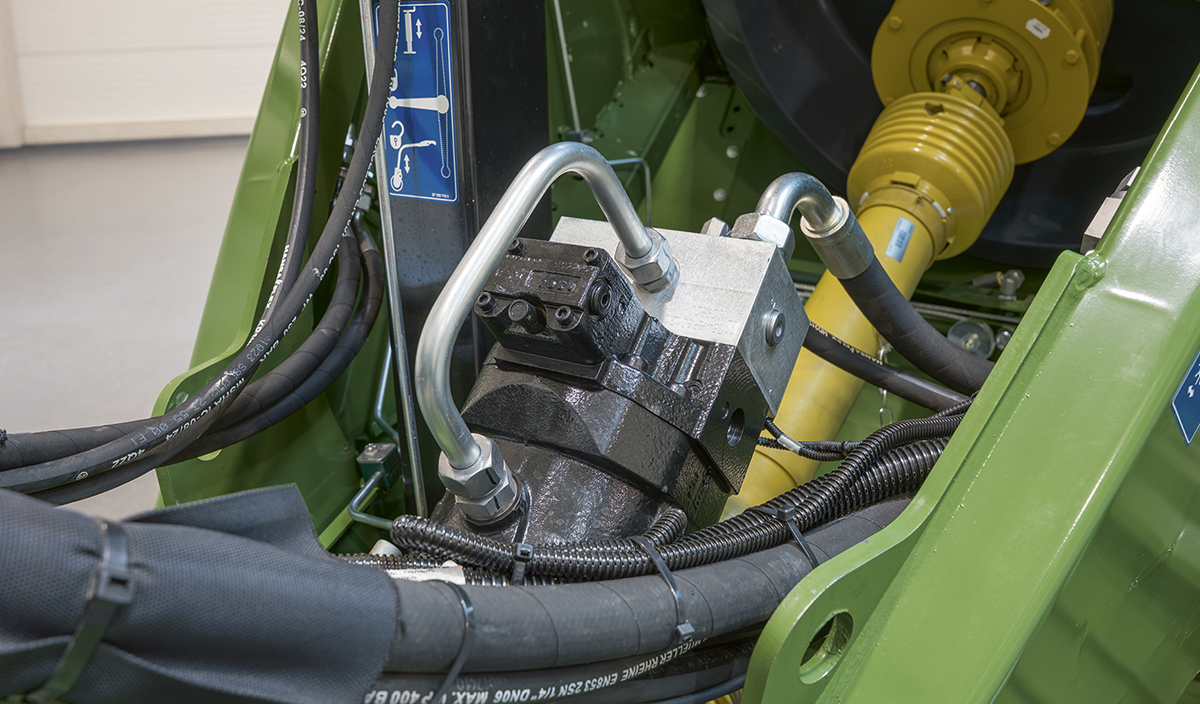

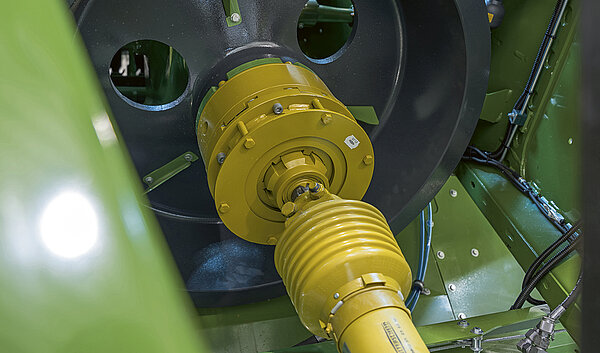

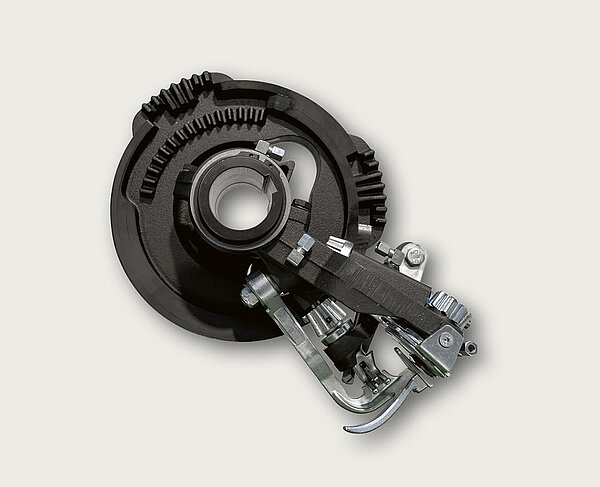

Hydraulically supported start-up

An angular gearbox installed in the drawbar of the KRONE BiG Pack HDP II 1290 (VC) ensures the straight and low-wear operation of the main universal shaft. A hydraulic starter aid is installed here as standard, which in comparison to the preceding model has a significantly more powerful start-up torque thanks to the new hydraulic motor, and depending on the oil volume of the tractor has a significantly higher final rotational speed of up to 400 rpm.

Product video

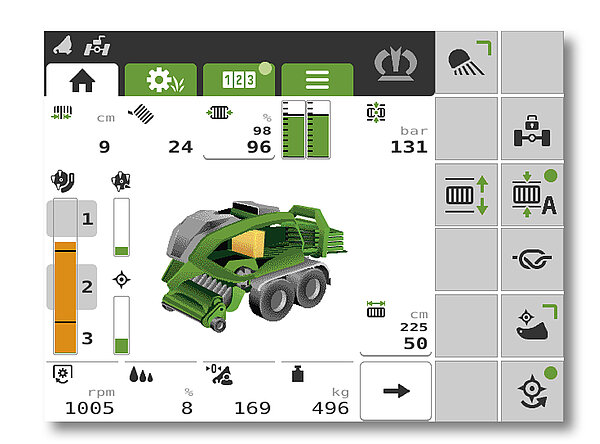

BiG Pack HDP II 1290 (VC)

KRONE BiG Pack HDP II 1290 (VC) – Equipped with eight revolutionary and snippet-free KRONE V-knotters, this is a professional machine offering maximum bale density, unmatched power and uncompromised efficiency even in the most difficult operating conditions. The BiG Pack HDP II 1290 (VC) sets new standards producing an extremely high number of bales and exceptional bale density in the shortest amount of time. Sturdy and designed for a long service life, it tackles the harshest conditions with ease, every day and in every season. This machine is the perfect solution for anyone looking for uncompromised power.

Product features

Equipped with eight revolutionary and snippet-free KRONE V-knotters, this is a professional machine offering maximum bale density, unmatched power and uncompromised efficiency even in the most difficult operating conditions. Die BiG Pack HDP II 1290 (VC) sets new standards producing an extremely high number of bales and exceptional bale density in the shortest amount of time. Sturdy and designed for a long service life, it tackles the harshest conditions with ease, every day and in every season. This machine is the perfect solution for anyone looking for uncompromised power.

The new generation of the BiG Pack HDP II 1290 An improved throughput rate, a higher baling density, increased comfort: The BiG Pack HDP II 1290 (VC) is setting new standards and is thus following the success of its predecessor.

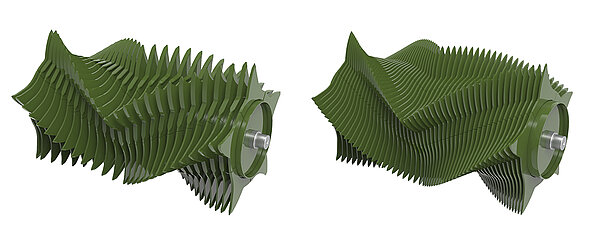

With a diameter of 72 cm, the cutting rotors guarantee the highest throughput rate even in challenging conditions. Steel plates on the 26-blade rotor ensure an even crop flow, excellent cutting quality, reduced wear and increased stability, especially in harvesting conditions with a lot of stones. Due to space restrictions, the 51 blade rotor does not have steel plates. Both rotors have a different design. Every cutting unit is equipped with exactly the right the rotor ex works to guarantee optimum coordination and maximise performance. Both rotors have five rows of tines, on the 26-blade rotor 27 stars are used across the width, while on the 51-blade rotor there are 52 stars.

The optional reversing system removes blockages in an instant by reversing the cutting unit. The feature is enabled from the cabin to easily remove foreign objects that cause the blockage.

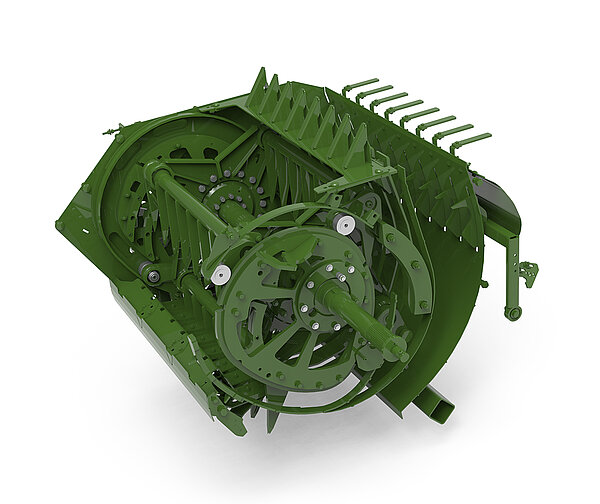

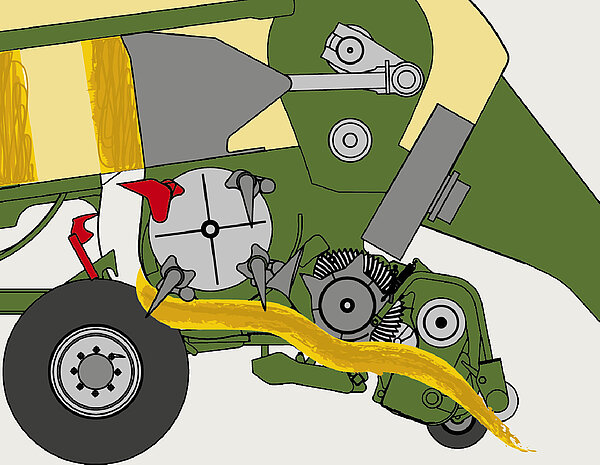

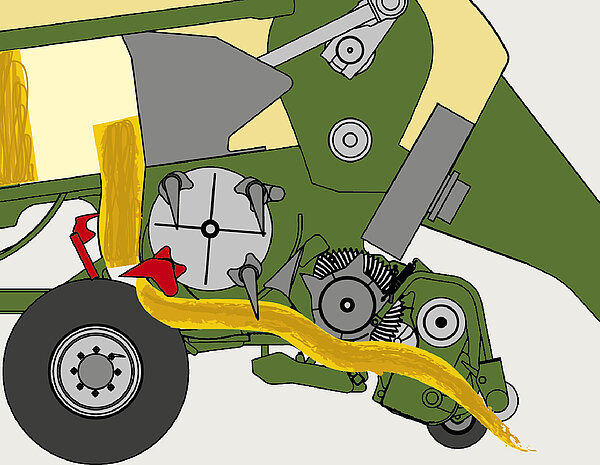

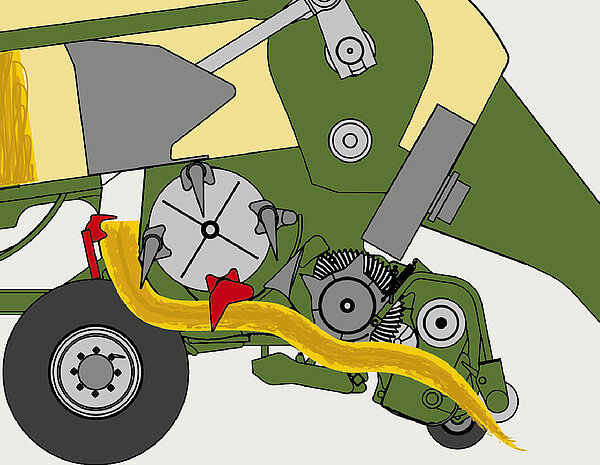

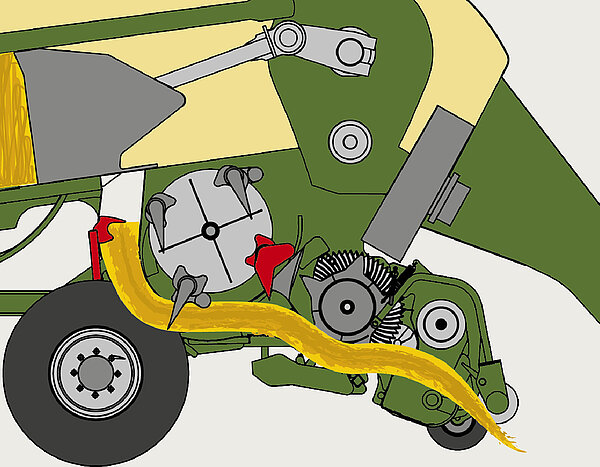

Maximum operator comfort and optimum machine utilisation are the parameters that translate into high daily outputs. Thanks to the filling level in the pre-chamber, which can be adjusted from the tractor seat, and the torque-based load indicator of the VFS, you always drive the BiG Pack at its limit. Although the throughputs are high, the material is constantly rotated and gently mixed and not exposed to high acceleration forces as on other feed systems. With the Variable Filling System, the new HDP II from KRONE is based on a system that has been tried and tested thousands of times around the world. The VFS system combines the advantages of continuous feed systems with those of volume-based systems thus ensuring even filling regardless of the swath shape and volumes.

The entire cam track of the feeder rake moves off path so the rake feeds the pre-compressed material into the baling chamber. The sensing rake and cam track then return to their initial positions.

When the pre-chamber is filled to capacity, the sheer volume of the material pushes the swing and retainer into the baling chamber. This clears the way into the bale channel and the collected material is conveyed. If not enough material is collected and the trigger threshold which can be set on the terminal is not reached, another collection stroke is initiated.

As long as the feeder cam track does not swing off path, the packers and the feeder continue feeding material into the feed chamber, pre-compressing it as they go. The sensor swing with its retaining tine traps the material inside the feed chamber, preventing it from entering the baling chamber.

The VF system uses three packer strips, one feeder strip and a sensing rake. The packers are controlled by a shared cam track, while the feeder strip is controlled by a separate pivotable cam track.

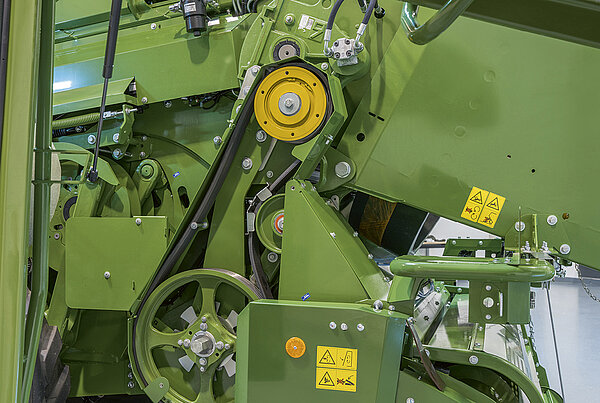

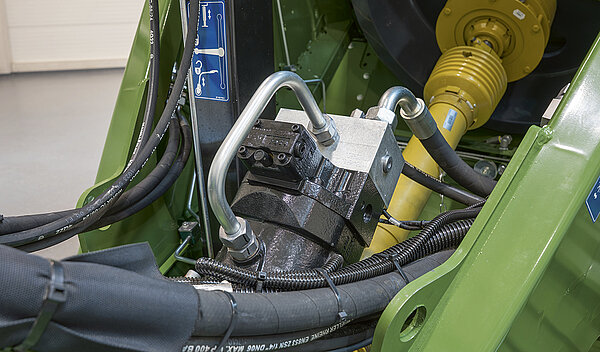

In addition to the VariCut cutting unit belt drive and bale channel control system, the hydraulic system of the KRONE PowerClean cleaning fan has its own enclosed on-board system and requires no oil from the tractor hydraulics.

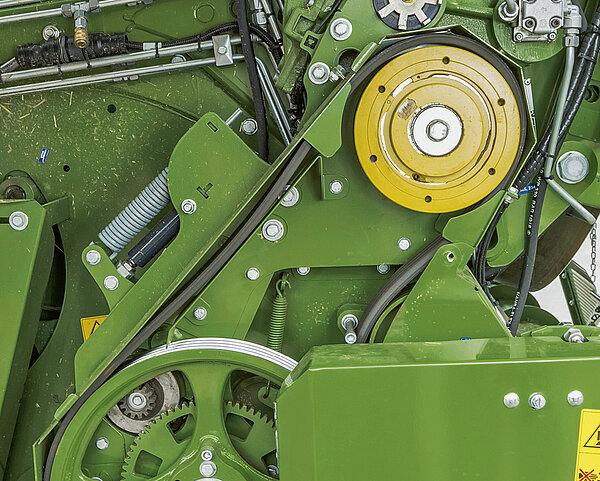

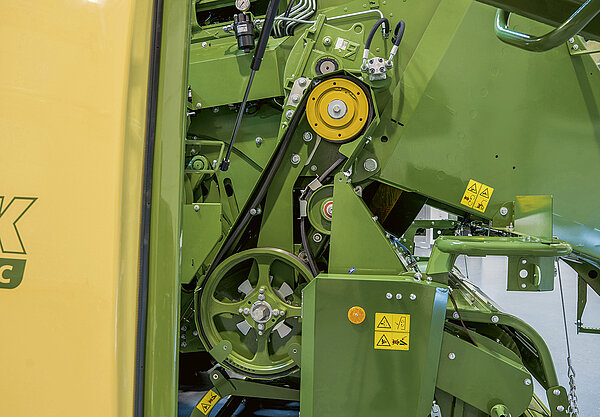

On KRONE big balers, power is transmitted to the packer and the knotters via robust, low-maintenance drive shafts, gears and overload clutches. Buying this drive technology is an investment into ependability and comfort.

On start-up, the driveshaft to the BiG Pack is protected by a slip clutch. When there is an overload an automatic cut-out clutch is activated protecting the baler effectively from the energy that is stored in the flywheel. The two clutches are located in front of the flywheel for easy access and servicing.

Large flywheels prevent bounce and guarantee a quiet running system. The flywheels absorb peak loads and the machine maintains a consistent work rate whilst requiring significantly less tractor power – for more peace of mind, better fuel efficiency and minimum wear.

An angular gearbox installed in the drawbar of the KRONE BiG Pack HDP II 1290 (VC) ensures the straight and low-wear operation of the main universal shaft. A hydraulic starter aid is installed here as standard, which in comparison to the preceding model has a significantly more powerful start-up torque thanks to the new hydraulic motor, and depending on the oil volume of the tractor has a significantly higher final rotational speed of up to 400 rpm.

The bale ejector can be split – you decide whether it is just the last bale that is discharged or whether the full bale channel is emptied. When enabling the ejector, the pressure in the bale channel is automatically reduced to a customisable level. The remaining residual pressure simplifies bale ejection and simultaneously ensures that the front bale does not slip backwards when subsequently driving on the road – the bale remains in position. In automatic mode, the bale ejector automatically carries out several cycles.

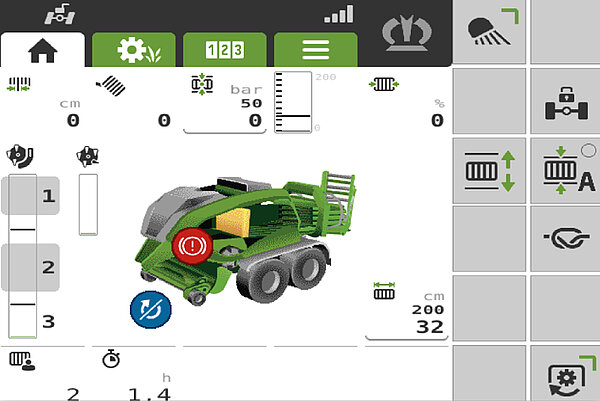

By default, the baler starts up in manual mode at a pressure of 50 bar. The first chamber filling should always be carried out in manual mode. After that you can select auto mode. Alternatively, you can choose and set a different default pressure between 0 bar and 200 bar. This, however, will disable the auto mode option.

The operator selects a density between 0% and 100% on the control box, and the baling force control automatically adapts the pressure in the baling chamber. This way, you get uniform and consistent bale densities also in varying conditions.

KRONE equips all BiG Packs with a star wheel that measures the bale length electronically. Arranged in the middle of the bale channel and protected from foreign objects and soiling by a lateral cover.

The BiG Pack features a strong frame end with mounting consoles and therefore allows the attachment of bale accumulators. In addition to various chutes, the machine is also available ex works in the "BaleCollect ready" version.

The BiG Pack HDP II 1290 (VC) has a continuous upper baling flap for maximum compression. It is also fitted with wear plates in the bale channel as standard ensuring minimal wear even at high throughput rates. The newly developed bale channel floor with a conically shaped profile ensures an even bale shape and reduces the amount of cleaning work required. Seven large hydraulic cylinders control the baling flaps – three of which are positioned on the upper flap. This increases power reserves especially when working with dry or slippy hay, provides high-density bales, maximises efficiency and delivers first class quality bales.

The design and functionality of the twine boxes has been improved considerably. The twine box is integrated in the side hood and can be accessed via an additional flap without any tools – dust and dirt are effectively kept out. Each side of the BiG Pack 606 has space for up to 24 spools weighing 15 kg each. Of course, standard 11 kg rolls can also be used. The larger capacity certainly increases the range and reduces downtimes.

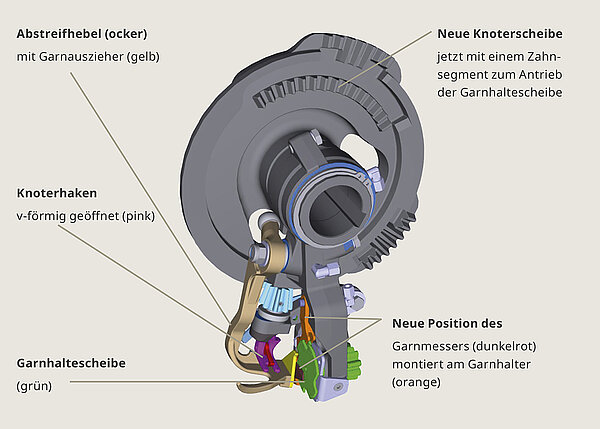

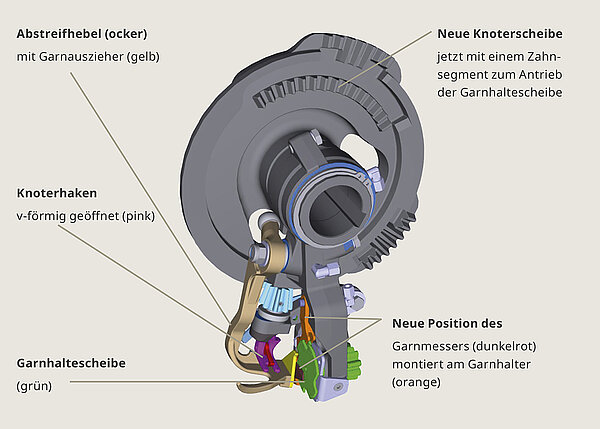

Der V-Knoter arbeitet äußerst zuverlässig und verschleißarm nach dem Doppelknoter-System von Deering, wobei der systembedingte Garnschnipsel nicht mehr wie in der Vergangenheit freigesetzt wird, sondern als Schlaufe in den zweiten Knoten (Startknoten) gezogen wird und dort für zusätzliche Stabilität sorgt.

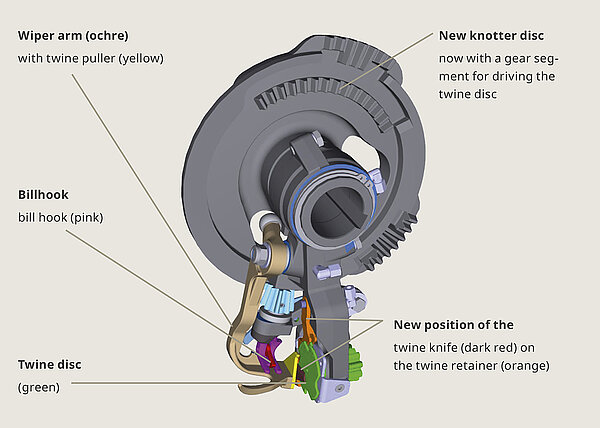

The extremely dependable and hard-wearing V-knotter operates to the Deering double knotter system. The snippets of twine generated by the system are no longer released like they were in the past, this design forms the snippets into a loop and pulls this into the second knot (starting knot), further increasing the stability.

The KRONE V-knotter is named after the V-shaped open billhook which makes it possible to pull the loop of the second knot, shaped as a loop knot, downwards. The otherwise system-related twine snippet of the double knotter is thus pulled into the starting knot of the bale as a loop, which increases stability, and does not remain on the bale.

The blade is now positioned directly in front of the twine disc. By rotating the twine disc between the two cycles of the billhook, the twine strands are pulled through the blade and separated. The wiper arm pushes the knot precisely off the billhook.

The twine disc and billhook are controlled via the modified contour and segmentation of the knotter disc. It is noteworthy, that in comparison to the standard Deering double knotter, the second gear segment for the twine disc has been removed.

The knotter bay is covered by a stylish plastic deck which gives maximum protection.

Two turbines feed the air from the rear into the knotter bay, creating an overpressure and preventing debris from depositing here in the first place. This means that no material gets onto the bale channel and causes contamination. From here, the exhaust air is directed to the area behind the twine boxes and down to the axles, keeping these areas clean too.

The on-board hydraulic system powers the unit effectively as soon as the PTO shaft is engaged. Superseding the existing pneumatic cleaner, the new system requires substantially less tractor power.

The large knotter bay opens easily without tools for convenient access to the knotters. The turbines stop automatically when the deck opens.

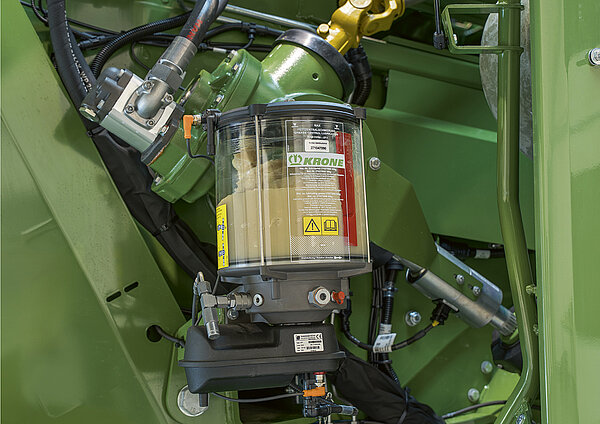

The steered axle is now much easier to service. All lubrications points with less-than-50-hours service intervals are now serviced by the auto lubricator. This cuts the time you spend servicing the machine and keeps the grease nipples clean and tidy.

The BiG Pack HDP II 1290 VC is fitted with 26.5" tyres as standard. 30.5" tyres are optionally available. The following dimensions are available: 620/55 R26.5", 710/50 R26.5" and 600/60 R30.5". All variants are equipped with high-quality radial ply tyres. The larger contact area of the tyres ensures excellent drag resistance and reduces the ground pressure especially in challenging conditions.

The spring-suspended Boogie tandem axle provides smooth and quiet running even at 60 km/h, taking strain off man and machine. The caster-steered rear wheels manage every turn treading gently on the valuable sward. When the machine reverses or travels at speed the steering axle is automatically straightened and locked hydraulically.

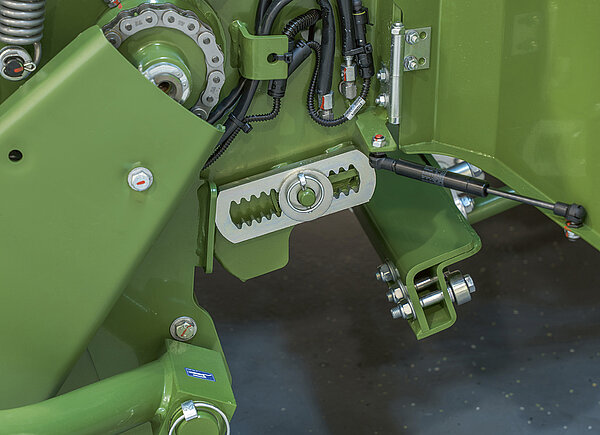

The hydraulic support jack ensures that attaching and removing the baler is particularly easy especially when using the K80 ball-head attachment. When operating the baler, the same control unit is used via a directional valve so that the crop press roller unit can easily be adjusted from the cabin.

The BiG Pack HDP II 1290 VC includes a bottom hitching as standard. The modular drawbar is designed for loads of up to four tonnes. The compact design and ability to mount the bearing block of the universal shaft in various positions ensure that optimum universal shaft runs can be achieved. Optional collision protector systems are available to protect tractor tyres especially when driving around tight curves. A choice of coupling systems is available that suit various national requirements.

The cutting system, the twine boxes, the bale chute and the pusher dogs as well as the LED work and service lights are operated from these BUS controls on the machine. The LED backlighting of the buttons gives you visual feedback on whether the individual functions have been enabled correctly.

All ISOBUS-compatible KRONE machines can also be controlled from the tractor’s existing ISOBUS terminal. Simply connect one single cable and enjoy your customised user interface on the terminal in the tractor cabin. Optional operation units, such as the CCI A3 joystick, can make the machine even easier to operate, depending on the tractor specifications.

The new ISOBUS-compatible CCI 1200 terminal with its 12” touch screen displays the views of two universal terminals (UT) on one screen. This allows the operator to control combinations such as a BiG Pack and a BaleCollect from one single terminal and view footage from several cameras on the same screen – a moneysaving feature that provides a better all-round view from the cab. The individual machine functions can also be displayed in the mini-view format on the bright, high-resolution display.

The CCI 800 ISOBUS terminal with 8” touchscreen serves as user interface and also as camera screen which feeds the images from the bale accumulator for example, offering multi-functionality that saves costs and frees cab space for uninterrupted view. The individual machine functions are shown in miniview format on the bright, high-resolution colour screen.

The compact DS 500 terminal has a 5.7” colour display screen with a clear layout for easy use. You can either operate the machine from the 12 function keys or the touchscreen and the dial control on the back of the device.

Forming an integral feature of the BiG Pack operator terminal, the dispenser offers various application modes – application at a fixed rate (l/min), at a throughput-related rate (requires the optional weighing chute), at one of three different moisture-level related rates (requires the optional moisture measuring system) or by flow rate percentage. All application rates are set up easily and conveniently in the menu settings.

Two flat spray nozzles at the end of each feed line apply a uniform spray on the material as it passes through the pick-up. As different nozzle sizes can be combined, a very wide range of dosing rates is possible. The nozzle holders fold out without tools for easy maintenance.

The pump unit, including filter and valves, is installed in a dustproof pump box on the yoke. The pump unit can be removed without tools in just a few steps, e.g. for frost-proof storage in winter. Useful features, such as a compressed air connection for emptying the lines, have been thought of, as has proper drainage of the pump box. An extra button operates the pump manually for service and maintenance.

The 400-litre tank for additives is a special development for BiG Pack where it is mounted on top of the baling chamber at the rear end of the machine. It has an electric filling level sensor that constantly sends its information to the cab terminal. The tank is either filled through the large and screened opening or through the side-mounted riser pipe at the rear end of the machine.

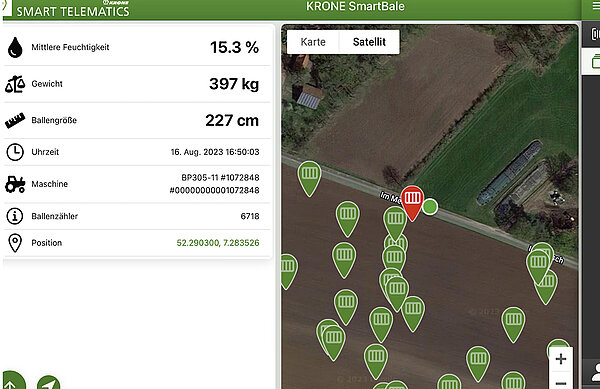

KRONE SmartBale displays all of the deposited square and round bales on a bale map. Depending on the baler equipment, the SmartBale app provides additional information such as moisture, weight, dimensions and whether the crops have been cut. Moist bales are colour-coded so that they can be easily identified and stored separately.

KRONE Smart Telematics offer fleet managers a bird’s-eye view of all machines and their data, keeping them on top of what’s going on in the harvest chain without having to make a single phone call. The system generates clear bale maps and detailed information on each bale. There is no better way to document a job! And with a few clicks, you can convert the data into simple PDF reports.

The KRONE SmartConnect telemetrics unit is the hardware element of the KRONE data management system. No matter whether you prefer the Agrirouter, KRONE SmartTelematics or simply E-Solutions software licences – KRONE SmartConnect with a multi-network SIM card is the easiest way to make a connection, because it logs automatically into the network that offers best reception at the site. KRONE SmartConnect is a standard feature on the BiG Pack.

The new digital camera uses the latest imaging technology to provide high-resolution images even in difficult lighting conditions. The 120° wide angle and sturdy design considerably expand the field of view on the BiG Pack, improve the monitoring of work processes, and increase the safety when shunting. Can be ideally combined with the CCI terminals or the 7" monitor – to ensure perfect control in every situation.

Would you like to keep track of whether the bale weight is meeting your customers’ needs? Then the optional bale chute with integrated weighing system is just the right technology for you. The terminal displays not just the weight of every single bale but also the total weight of the finished baling job.

The data from the optional moisture sensor at the entrance of the baling chamber are read out on the display screen, keeping operators informed on current conditions. The information is read out on a cab-based monitor. An alarm is issued automatically whenever a preset threshold value is exceeded.

Depending on the individual harvest and process chain, customers may want to have their bales deposited in specific patterns. To suit individual needs, BaleCollect offers five different strategies or modes of depositing the bales in the field. The ‘3 bales” or ‘3+1 bales’ modes are used to deposit all bales on or near the headland. By comparison, silage bales will be deposited to the ‘2 bales side by side’ mode or the ‘2 bales apart’ mode. These strategies are selected in harvest chains where the following wrapper is wrapping two silage bales into one pack or even picks up the bales itself. Of course, the operator can also push off the bales manually at any time by pressing a button. A new feature allows operators to drop the bales along as many as five waylines for more uniform results and convenience.

The BaleCollect platform can store up to three bales that leave a 120 cm chamber or up to five bales from an 80 cm chamber. When a bale leaves the chamber it is pushed to the right or left side by a bar, clearing the way for the next bale to enter the platform. All bales are automatically pushed off the platform according to the unloading mode selected by the operator.

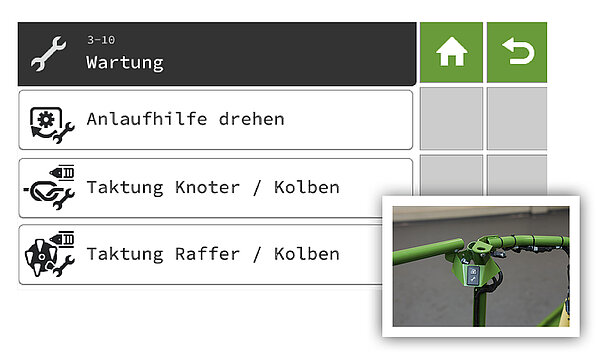

The new maintenance mode simplifies work on the machine. The hydraulic starter aid enables spinning mode for the baler to be activated easily and safely at the touch of a button. The integrated self-check function automatically checks the correct position of the piston, pre-chamber, and knotter. This saves time, increases operational safety and minimises the risk of incorrect settings.

To maximise practicality, the BiG Pack HDP II 1290 VC is fitted with a compartment beneath the bale channel as standard. It provides room for a tool box in which important auxiliaries can be stored and are accessible at any time. The protected position beneath the channel guarantees tidy and clean storage – perfect when working hard out on the field.

An extra water tank with an integral soap dispenser sits at the rear of the machine, allowing you to wash your hands after a brief intervention on the machine and get back on the tractor with clean hands.

The BiG Pack HDP II 1290 VC offers longer maintenance intervals and less time required for the work. The central lubrication with a large 8 kg reservoir is provided as standard and considerably reduces the amount of maintenance work required. A consumption indicator also reliably informs the driver when the filling level is too low.

The twine boxes beneath the side panels lower hydraulically to a convenient height. They are opened without tools for optimum access to and easy replacement of the twine balls.

A large maintenance platform with non-slip flooring positioned all around the knotter unit of the BiG Pack HDP II 1290 VC provides the best access to all of the relevant components. Foldable railings and an integrated ladder guarantee work can be completed conveniently and safely even in the event of longer service intervals. The platform is seamlessly integrated in the machine structure providing sufficient space to complete servicing work on the twine system or knotter unit quickly and ergonomically. All of the steps are made of sturdy step grid metal.

The right model for every field of use

| BiG Pack HDP II 1290 | BiG Pack HDP II 1290 VC | ||

|---|---|---|---|

| Chamber width x height (cm) | 120 x 90 | 120 x 90 |

configure

|

| Bale length (m) | 0.50 - 3.20 | 0.50 - 3.20 |

configure

|

| No. of double knotter | 8 (series) | 8 (series) |

configure

|

| No. of plunger strokes/minute | 45 | 45 |

configure

|

| Power requirement kW/hp | 170 / 231 | 190 / 258 |

configure

|

|

configure

|

configure

|

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)