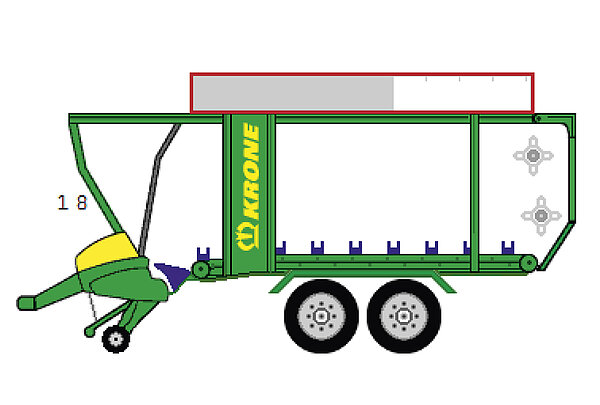

The key to viable farming is boosting efficiencies, cutting costs and utilizing equipment to full potential all year round. This is the scenario in which KRONE developed the ZX dual-purpose wagon. Dual-purpose means these machines serve as both self-loading forage wagons with discharge rollers and forager-filled forage wagons in maize and grass.

- The world's most powerful self-loading and harvester-filled forage wagon – thanks to the KRONE Powerbelt driveline with a transmission capacity of up to 400hp

- Camless pick-up with hydraulic drive and electro-hydraulic suspension

- Pivoting headboard increases capacity from a compact build

- Pull-out blade cassette with 48 individually protected blades

- Three standard discharge rollers on ZX GD models. Overload protection comes from a clutch in the main driveline.

- Optional SpeedSharp blade grinder

- Axles with hydraulic auto-levelling system

- PowerLoad auto filling system with auto chain-and-slat floor control

Product features

- OptiGrass

- Camless pick-up with hydraulic drivewith hydraulic relief

- Integral rotor and SplitCut for optimum conditioning – provides for an optimum cut

- Pull-out blade cassette with 40 or 54 individually protected blades

- Optional SpeedSharp blade grinder

- Pivoting front wall increases capacity from a compact build

- Axle assembly with hydraulic auto-levelling system

- Premium lighting Standard

- Options, which are worthwhile!

The KRONE ZX dual-purpose loading and forage transport wagon is impressive all along the line thanks to its modern design, innovative technologies and excellent forage quality. With the high-performance 'OptiGrass 28 and 37' cutting systems, it offers a clean, precise cut as well as structured and homogeneous forage conditioning across the entire width. Maximum power and efficiency round off the programme. The ZX sets new standards in the high-performance loading and forage transport wagon segment.

- Versatile

- Efficient

- Economical

- Operator comfort

Working economically means: boosting efficiency, cutting costs and utilising equipment to its full potential all year round. This is why KRONE developed the ZX loading and forage transport wagon. Dual-purpose means these machines serve as both loading and forage transport wagon in maize and grass.

- Clean cut in theoretical length of 28 or 37 mm

- Optimal structure gentle conditioning under all conditions

- Homogeneous uniform conditioning of each stalk over its full width

- Precise wide steel plates and blades arranged for shear cutting

- Perfectly coordinated precise interaction between pick-up and cutting rotor

- Innovative new integral rotor with unique divider wall system

Thanks to the KRONE OptiGrass system, the forage quality is clean, homogeneous and uniform. This is possible due to the precise cutting method with a choice of cutting lengths of 28 or 37 mm. Thanks to the perfectly coordinated technologies, conditioning is gentle, resulting in a clean and high-quality result.

A high milk yield is the decisive factor for the economic success of a farm. The forage intake required for this is ensured in particular by tasty and pure forage. To ensure clean pick-up without the introduction of raw ash, fungi and yeasts, the OptiGrass concept with its wide oscillating pick-up and excellent scanning characteristics offers the right technical solution to achieve perfect crop pick-up.

- Hydraulic drive independent of the cutting rotor

- Automatic or manual rotation speed adjustment to the driving speed

- Maintenance-free and low wear

- Uniform filling staggered arrangement of the tines in a W-shape

- Large pivoting range

- Electrohydraulic relief for even better sward protection

The EasyFlow pick-up with hydraulic drive is the ideal solution for demanding requirements. With its 6.5 mm thick double tines in a helical layout, it meets the most demanding requirements in ease of maintenance and pick-up capacity. The hydraulic drive integrated in this pick-up offers an even larger work width, which helps to collect even more material at an optimum driving speed and maximizes the intake capacity.

- OptiGrass 37 mm cutting distance with 40-blade cutting unit

- OptiGrass 28 mm cutting distance with 54-blade cutting unit

- KRONE PowerBelt the drive concept for extremely high throughput rates.

- Integral rotor with augers high-performance crop flow with maximum pick-up width

- KRONE SplitCut optimum conditioning over the entire rotor width

KRONE OptiGrass – state-of-the-art technology for perfect forage conditioning. The 40-blade cutting unit with a cutting distance of 37 mm and the 54-blade cutting unit with a cutting distance of 28 mm ensure optimum forage quality. KRONE PowerBelt ensures extremely high throughput rates and the KRONE SplitCut system ensures gapless conditioning across the entire rotor width.

- Top cutting quality Shear cut

- Theoretical cutting length: OptiGrass 28 mm with maximum 54 blades | OptiGrass 37 mm with maximum 40 blades

- Central blade group control system: 0, 20, 20, 40 blades | 0, 27, 27, 54 blades

- Blade changing without tools and with central locking

KRONE OptiGrass cutting units offer wide tine holders and closely spaced, guarded blades which provide an easy and precise cut, similar to a pair of scissors. Two cutting units with 40 or 54 blades are available for optimum conditioning. Thanks to the central blade group control system, the cutting length can be varied at any time between a half and full set of blades, allowing cutting distances of 28 or 56 mm or 37 or 74 mm. OptiGrass therefore offers a flexible solution for different cutting lengths.

- Blade cassette can be swivelled out to the side

- Blade changing without tools and with central locking

- Central operation on the left side of the vehicle

- 40 or 54 sharp blades on the side of the blade cassette for a quick change

You change the blades without tools and without leaning over the blade cassette which is now alongside the machine. lower the blade cassette, swing it out to the side and remove the blades without tools – a time and cost saving system.

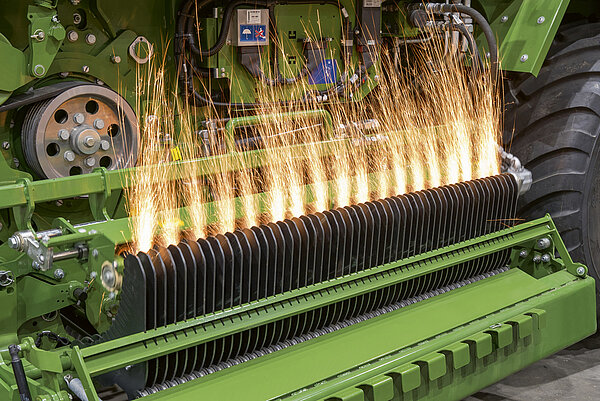

- Sharp blades in no time – convenient and fast

- Simultaneous sharpening of half (OptiGrass 37) or a third of the blades (OptiGrass 28)

- No annealing of the blades thanks to "cold grinding"

- Simple design, maximum functional reliability

- No sparks flying under the wagon

Sharp blades are fundamental for clean and smooth cuts. This is why KRONE developed SpeedSharp, the unique blade grinding device. The trademark of this system is its simplicity.

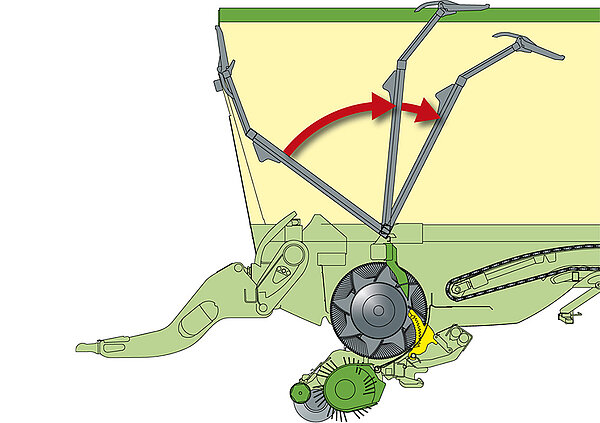

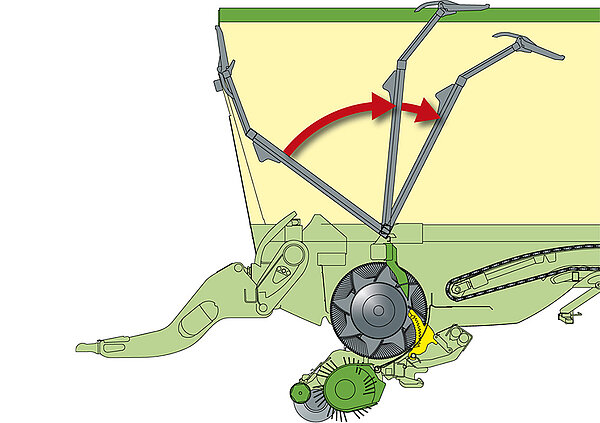

- Up to 4.5 m³ additional loading volume

- Quick and reliable unloading of the wagon

- Relief of the scraper conveyor

- Variable baling pressure when used as a loading and forage transport wagon

Loading and unloading rates are important parameters in viable farming and contracting. The pivoting front wall boosts the machine’s loading capacity by up to 4.5 m³, pre-compresses crops as required and acts as an unloading aid by emptying the machine faster and effectively.

- Conical frame and design easier unloading

- Double scraper conveyor with drive on both sides more power

- Flat link chains extremely durable

- Automatic fast unloading system as standard load-dependent engagement of the scraper conveyor rapid traverse

It takes high-end engineering to withstand the permanent exposure to huge masses of material on the loading area and fast unloading processes. Two scraper conveyors, i.e. four flat link chains and two motors and a conical design that tapers to the rear will always deliver.

A sensor on the scraper conveyor displays the information on the terminal about the discharge and remaining capacity of the loading space. This gives you an overview of the current filling level at all times.

- 3 discharge rollers with large diameter (47 cm) as standard

- Discharge roller protection with 3,000 Nm in the main universal shaft

- Automatic scraper conveyor stop via the lower discharge roller

- Higher speed for the two lower rollers – uniform forage discharge

The first step in producing high-quality silage is to achieve a perfect forage distribution. The ZX GD models with three large-diameter discharge rollers meet these requirements. The material layers are evenly unloaded across the full length of the clamp, perfect for subsequent rolling.

- Optionally with tandem or tridem chassis

- Safe handling at top speeds of up to 60 km/h on the road

- Maximum stability on slopes – reduced danger of tipping over

- Equal load distribution on all wheels – reduced brake wear

- Optionally with 30.5" tyres to reduce ground pressure

- With axle steering Protection of the sward, reduced tyre wear

- Optionally with hydropneumatic suspension for even greater comfort

The caster- and force-steered tandem axles have hydraulic pressure compensation for all requirements and needs. Each running gear ensures roll stability when travelling at speed around bends as well as stability on slopes. These axles offer maximum safety and operator comfort.

The steered axles are standard specification. Tracking excellently in headland turns and curved lines, these wheels eliminate the risk of scuffing, protect the sward and take off stress from the running gear.

- Optional electronic EBS braking system features

• ALB automatic load-dependent brake force control

• ABS anti-lock braking system

• RSS roll stabilisation support - Contactless electronic forced steering

Larger and faster tractors and higher transport volumes and payloads require a rethink in terms of safety. Therefore, KRONE offers an electronic braking system that has already proven its worth in the commercial vehicle sector. In addition, steered axles help protect the swath and provide added safety.

- Optional for the tandem axle, standard for the tridem axle

- Smooth and quiet running, low abrasion, ideal for manoeuvring

- Electronic forced steering – can also be operated manually for counter-steering

- No additional coupling required – for greater tractor flexibility

Forced-steer wheels protect the sward and the tyres when driving around corners, reducing the load on the tandem or tridem chassis and making it easier to pull the wagon. When shunting, driving on a slope or clamping, the electronic system allows the operator to actively intervene and change the position of the steering axle so that the wagon countersteers.

By electronically transmitting the steering angle, the contactless forced steering allows a higher steering angle and prevents possible damage due to collisions with the tractor tyre. No linkage interferes with the full steering angle of the tractor-trailer combination. Thanks to the electronic control, the steering characteristics can be adjusted perfectly to different driving situations.

- Excellent manoeuvrability thanks to small, compact design

- Higher drawbar loads with bottom hitching

- Quiet driving with drawbar suspension

- High driving comfort with ball-head attachment

Increased total weights have made bottom-hitching the most popular type of attachment for loading and forage transport wagons. This reduces the load on the tractor’s front axle and ensures the four-wheel drive system is more effective.

The ZX dual-purpose forage wagons have bottom-mount drawbars, The combination of the stable construction and a ball-head attachment allows drawbar loads of up to four tonnes. The narrow and compact design of the drawbar allows a minimum turning radius.

- Premium lighting package as standard

- Excellent all-round visibility at night thanks to two powerful LED working lights at the rear

- Safe in the field and on the road with front position lamps and reflectors

- The load always in view Thanks to LED light strips installed as standard in the loading space

- Two additional working lights can be quickly retrofitted thanks to prepared cable position

The KRONE ZX's premium lighting package not only enhances safety, but also increases nighttime productivity. The Premium package provides optimum lighting of the surroundings, the loading space, the crop flow and the drive components. Additional working lights can be retrofitted as an option.

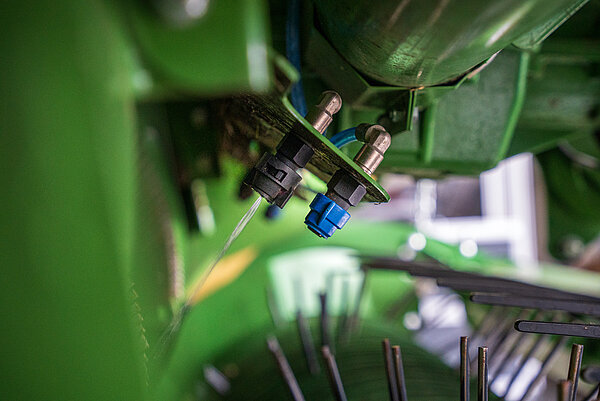

- Spreading above the pick-up using flat jet nozzles

- 200 litre tank capacity optimally positioned for access at the rear

- Easy cleaning of the system

- Removal of the pump unit without tools

- Convenient operation via the terminal

- Different modes for optimal dosage

The KRONE ZX has an integrated dosing system with a 200-litre silage additives tank which can be operated in different modes. The pump unit, including the filters and valves, is installed in the rear of the vehicle to save space. An electronic filling level indicator enables reliable and fast monitoring of the silage additives supply.

- Loading space cover for loss-free transport

- Camera with colour display on the monitor

- Weighing device for an exact measurement

- KRONE SmartConnect telemetry unit optimal data management

The loading space cover ensures clean transport even when driving fast and increases safety in road traffic. A camera helps to see the working environment better, making work easier and safer. The electronic weighing device can be used to measure the loading quantity precisely. The KSC control unit ensures rapid transmission of the recorded data.

The ZX can be optionally equipped with the KRONE Smart-Connect telemetry unit. This interface is used with GPS and WLAN function as the basis for data management. Telemetrics allow managers to track the wagon and record all major data and transmit them to the office. This is the modern way of farming.

- Operator comfort

- Clear concept

- Easy handling

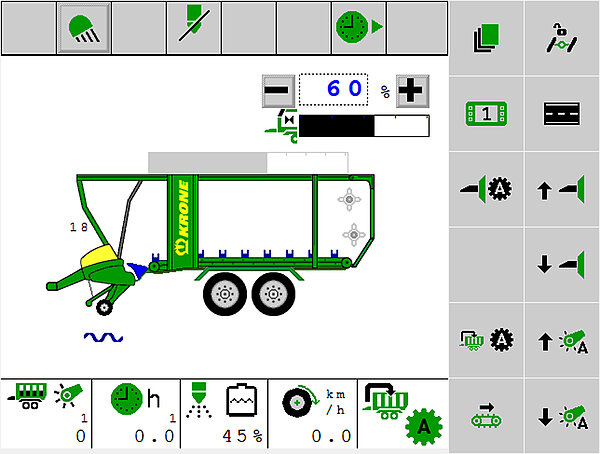

- CCI-ISOBUS – One box for everything

Operator comfort is essential. Our shockproof operator terminals are compact, clear-cut and easy to operate. They feature backlit buttons to reduce operator fatigue during those long shifts well into the night. The CCI terminal is a universal operator control unit, which is compatible with a wide variety of ISOBUS implements from many manufacturers.

The user interface of the KRONE ZX is particularly user-friendly thanks to its simple and intuitive operability. Various work steps are illustrated by visualisation, such as rotating discharge rollers. More comfort is provided by the configurable display bar which can be used to individually adjust the user interface to the user's requirements. Automatic functions, such as the PowerLoad automatic loading system, the automatic unloading system and the drawbar control system, are also available.

The compact DS 500 terminal has a 5.7-inch colour display screen can be operated with 12 function keys, the touchscreen or the scroll wheel on the back. An optional joystick is available for even more convenient operation.

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN (UK):]](/fileadmin/_processed_/4/2/csm_AK_ZX470GD_1_232313_1efc733e2c.jpg)

![[Translate to EN (UK):]](/fileadmin/_processed_/c/4/csm__AK_7979_237554_a7c2931c13.jpg)