With parts of the country already well underway with their first cut of silage, farmers are being reminded to keep on top of machinery maintenance and farm safety throughout the rest of the season.

Ben Davies, product manager at Krone UK, shares his advice on why keeping on top of mower maintenance is so valuable in achieving high quality silage.

Mr Davies says: “There’s no one size fits all approach in knowing when to change your mower blades. Different types of grass will affect the rate at which the blades are dulled, and even the age of the grass being cut.

“Inevitably, the mower will also come into contact with stones or mole hills that will cause more damage to the blade, so you need to be mindful when in the field of what the conditions are like – it may prompt an extra look at the condition of the blades if the field was especially challenging,” he says.

“It can be tempting to ignore a blunt blade when it still appears to be cutting the grass well but I wouldn’t avoid investing in a new, sharp blade if you want to maintain silage quality beyond the first and second cut, particularly if you’re looking to achieve a successful multi-cut system.

“A clean cut can lead to a more efficient recovery period between cuts, which could make the difference needed to achieve an extra cut and get more silage in the clamp. Ultimately, a cleaner cut is less damaging to the plant, allowing it to retain more moisture and begin to re-grow.

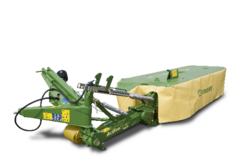

“Krone’s EasyCut mowers are fitted with the SafeCutTM hub as standard, so when the blade hits an obstacle the shock load is transferred to a roll pin, which breaks to reduce the risk to the blades.”

Mr Davies also explains that there is a higher power demand for a machine operating with a dull blade.

He explains: “It may seem more cost effective to run the blades right down, however, the impact this can have on crop regrowth and fuel efficiency may outweigh this saving. New blades need less diesel to work, as it takes less energy to cut through the grass in the first place.

“To maximise fuel efficiency, it’s also vital to make sure the mower as a whole is set up correctly, which includes setting the conditioner at the right level – this will depend on the size of the crop.

“This needs to be adjusted accordingly and with the heavy first cut grass silage we’re experiencing this season, and with the high material flow through the mower, the conditioner gap needs to be opened up as wide as possible to provide the desired effect but avoiding excessive power consumption,” he explains.

“Optimising the float of the cutter bar will also help with overall efficiency, by ensuring the mower bed follows the ground contour without bouncing, which can cause an uneven cut. If set too heavy, the mower will smear the soil and contaminate the silage, along with potentially leading to premature bed wear.

“With it being it such a wet spring, it’s also important to avoid driving over the swath where possible to avoid soil contamination – it may even be worth considering if it’s practical to clear the headlands first to reduce the risk,” concludes Mr Davies.

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)