The KRONE blade sharpener on BiG X forage harvesters scoops a DLG Silver Medal

The new and patented “Blade sharpener on forage harvesters that requires no manual adjustment” will be awarded a DLG Silver Medal at Agritechnica in November. The prize recognizes an innovative technology that sharpens the blades on the chopping drum and stands out for a longer maintenance interval, high operator comfort and less abrasion.

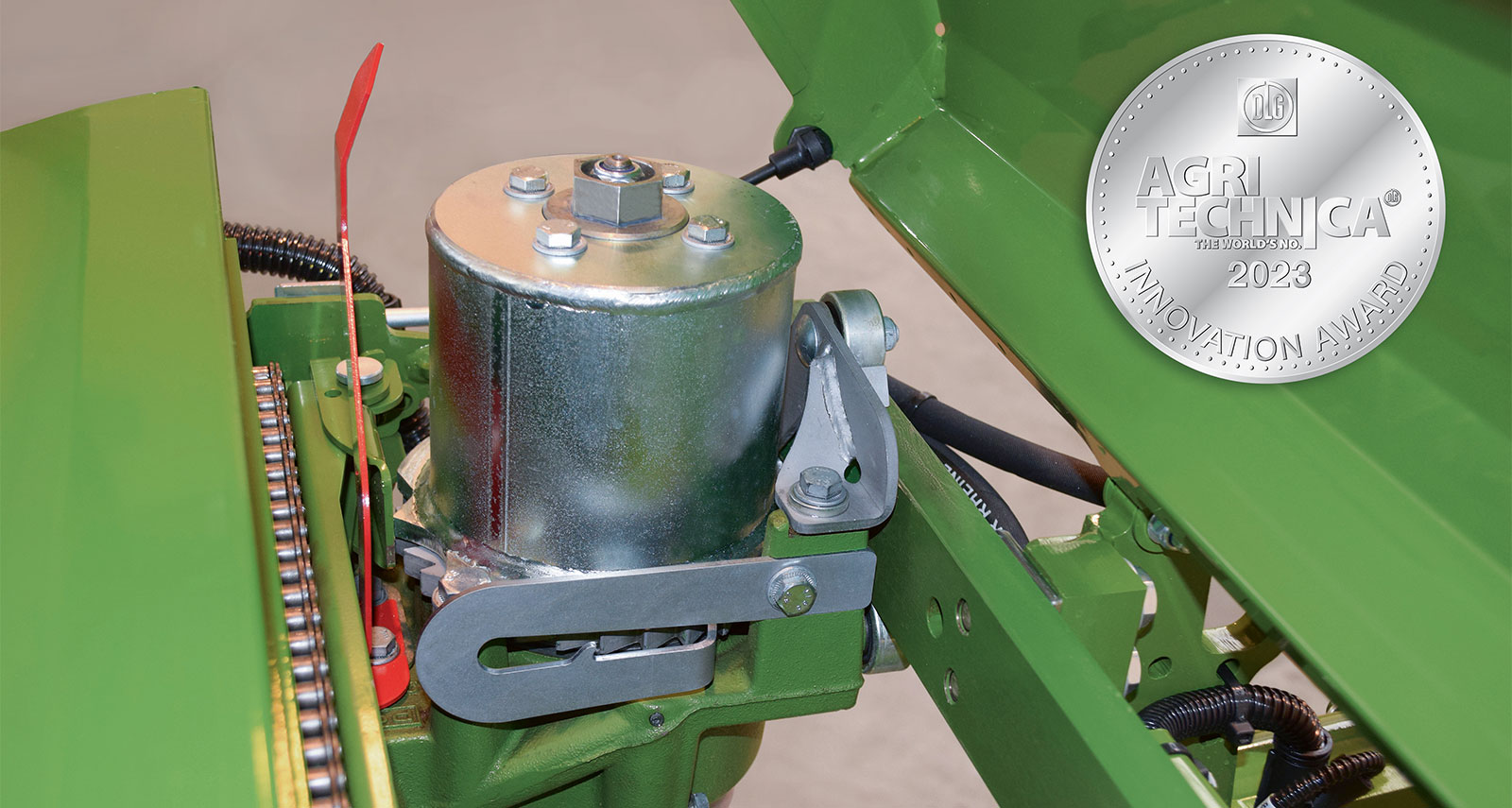

Spelle, September 2023. The novel blade sharpener from KRONE stands out for 2200 grinding cycles without requiring manual resetting of the grinding stone. The new system offers a five times longer service interval than traditional systems which need servicing after 400 to 450 grinding cycles. This involves a number of advantages. The new system is based on a new mechanism integral telescoping thread that adjusts the position of the grinding stone.

Saving time and reducing abrasion

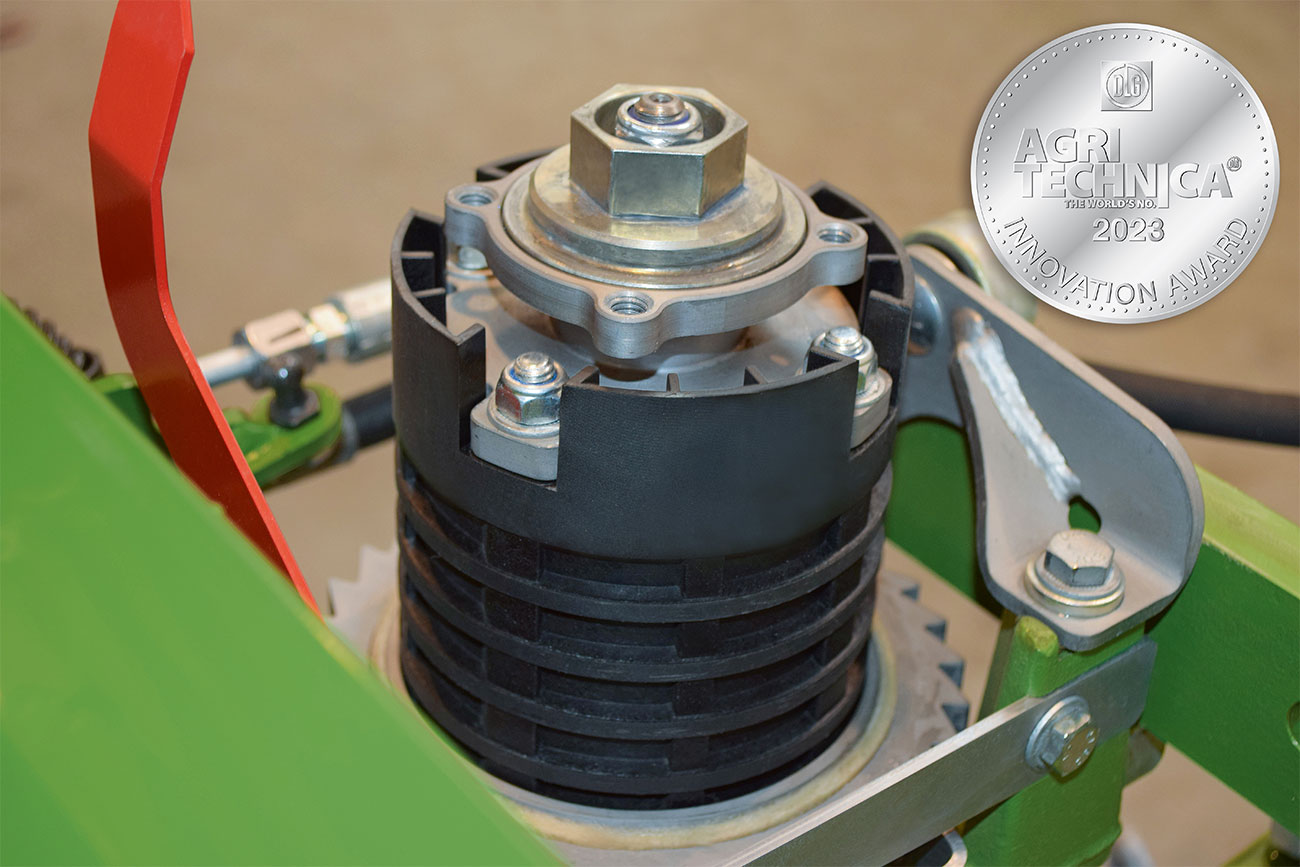

Thanks to the innovative attachment system, the entire surface of the stone is now available for grinding. This compares to traditional clamping systems where only 40% to 55% of the surface of the stone is actually available for sharpening. Hence the new system offers increased service life and productivity. Replacing the grinding stone is easier, too. Operators simply undo two screws and remove the downholding deck from the stone and then remove the stone from its carriage. Unlike existing grinding systems, this enclosed and patented assembly offers effective protection from contamination for troublefree operation during the entire service life.

Optimising the quality of chop

The new sharpener has also a positive effect on the quality of chop. The new guide shaft is more lightweight and smaller in diameter (from 50mm to 40mm). In addition, it is now propped in four positions at 267mm intervals instead of 1160mm intervals. These modifications increase its stability and reduce vibration and grinding forces and effectively cut out the risk of deformation and bouncing. The grinding faces form a minimum circumscribed circle which means that the shear bar on the chopping drum aligns centrally relative to the two rows of blades and at a uniform and consistent distance. It is this detail that translates into a significant improvement of the quality of chop.

Summary: The new sharpener carries out 2200 grinding cycles without requiring any manual readjustment - a unique and most efficient KRONE solution for sharpening the blades on a chopping drum. The new development is a massive time saver, reduces service and maintenance, saves costs and optimises the chopping quality and makes for more consistent abrasion of all chopping components.

Press contact

Markus Steinwendner

Head of Marketing KRONE Agriculture

+49 5977 935188 20

markus.steinwendner@krone.de

www.krone-agriculture.com

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)