2000

On 20 May 2000, it was time for the official presentation of the first KRONE forage harvester prototype called BiG X. The 540 hp forage harvester started its first test runs as a 40 km/h high-speed version. Despite the requirement that ‘form follows function’ (function is more important than appearance), it succeeded in creating a future-orientated design that was unanimously praised by the trade press. The prototype of the BiG X was created in 1999 and early 2000. All the functions, especially the new electronics, were gradually put into operation.

2003

Following its rollout in 2000, the BiG X, after proving its commercial success, is available in two models in 2003: the BiG X V8 (605 hp) and the BiG X V12 (780 hp) as well as the EasyFlow grass header and 8, 10 and 12-row EasyCollect maize headers. The KRONE maize header with the endless collector principle differs significantly from all other existing row-independent maize headers and offers clear advantages for the farmer: excellent handling, low weight, reliability and low maintenance. Parallel to the rollout of the first BiG X series, KRONE also presented the new BiG X service team, at that time a six-strong customer service team. The specially trained service staff presented their personal BiG X customers with a BiG X service card with a BiG X hotline, which was available around the clock throughout the season.

2005

With over 200 units in operation worldwide, the development of the second generation is nearing completion. The new BiG X prototype is equipped with two synchronised six-cylinder engines and thus achieves a rated output of around 1000 hp. In parallel to the increased drive, KRONE has also increased the power of the forage harvester heads and equipped the chopper with a 14-row maize header, which corresponds to a working width of 10.50 metres. Since autumn 2005, KRONE has been offering AutoScan, a sensor that detects the maturity of the maize plants, for all EasyCollect maize headers. The electronic control of the chopper then regulates the chop length fully automatically. The benefits are obvious: green (moist) maize is automatically chopped longer so that the forage retains its structure. For brown (dry) maize, a shorter chop length is selected to achieve better compaction in the silage stack and prevent secondary fermentation.

2009

The VariStream Crop Flow System is introduced for the BiG X 650 in 2009. The sprung drum floor is connected to the anvil of the counter-blade at the front. When it is adjusted, the distance from the drum floor to the knife remains constant. This means that the chopping quality does not change even if the sprung drum floor deflects due to an uneven crop flow. With the spring-mounted rear wall of the throwing accelerator, you can achieve the highest throwing performance in all operating conditions and load the transport wagon with pinpoint accuracy. This clever solution not only impresses BiG X customers, but also the DLG - which is why KRONE has been awarded a silver medal for it.

2010

With the third BiG X generation - consisting of the three models BiG X 700, 850 and 1100 - KRONE has further strengthened its reputation as a manufacturer of high-performance shredders. Gone were the days of twin engines being replaced by V12 units. Despite the new PowerSplit system, which allows the engine power to be reduced if necessary, customers wanting a machine with 450 to 700 hp still had to wait three years.

2013

The wait is over! The BiG X 480 and 580 signalled KRONE's entry into the lower horsepower range in 2013, applying the experience gained from the BiG X 500. The drum width has been reduced from 800 mm to 630 mm to achieve a better power to chop width ratio. The addition of an independent rear wishbone suspension significantly improves driver comfort, rear visibility and manoeuvrability. In line with the new, small chopper series, which was completed two years later by the BiG X 530 and 630, KRONE also presented new maize headers at Agritechnica 2013, both in the two-part and three-part segment. A particular highlight of the trade fair was the first six-row maize header from KRONE, the EasyCollect 450-2 with a working width of 4.50 metres. The BiG X has been produced in the new production hall for self-propelled harvesters in Spelle since October 2013. Special features of the 265 m long and 27 m wide new building include state-of-the-art assembly lines with a high-bay warehouse for a special logistics concept as well as end-of-line test stands where the finished machines are checked for all functions.

2017

The fourth BiG X generation, BiG X 680, 780 and 880, is introduced. The focus is on improved performance and operating comfort with wishbone rear suspension and a new cab design in which the LiftCab can be moved upwards. Often an everyday working day in autumn: the maize crop is extremely high and the forage harvester driver always has a high ‘wall of maize’ in front of him throughout the working day. The driver can now raise the entire cab, which is positioned on a hydraulic scissor lift table, by 70 cm at the touch of a button. This innovation was honoured with a DLG silver award at Agritechnica.

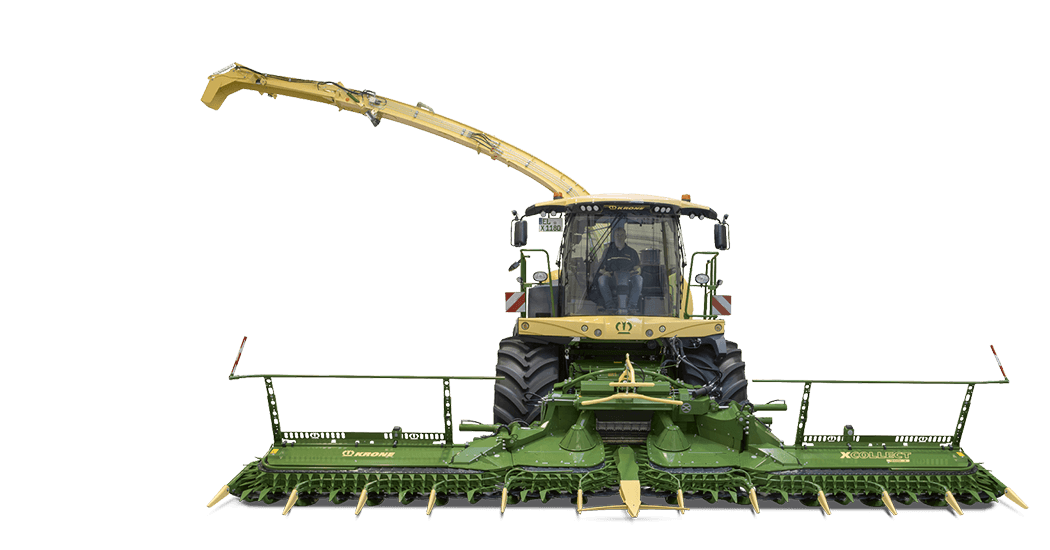

2018

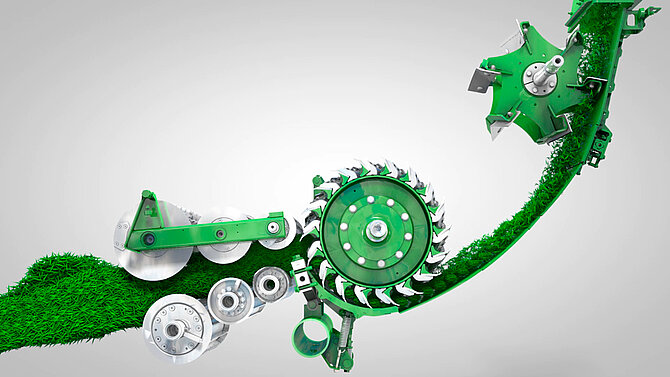

The BiG X 1180 completes the forage harvester programme in 2018. The increase in engine power is due to the Liebherr V12 engine with a displacement of 24.24 litres and 850 kW (1156 hp). This means that KRONE currently offers the most powerful forage harvester in the world, which also has a practical engine concept. This means that maintenance intervals for oil, filters and valves are only required every 1000 operating hours. In response to the increasing focus on forage quality, all forage harvesters in the large series are now available with the larger OptiMaxx corn conditioner. At the same time as the new BiG X 1180, KRONE is presenting the new maize header of the XCollect series as an addition to the proven models of the EasyCollect series. This is KRONE's response to different requirements and harvesting conditions worldwide. The new XCollect is available in three working widths: 600-3 (8 rows, 6 m), 750-3 (10 rows, 7.50 m) and 900-3 (12 rows, 9 m). A special feature of the XCollect is the separation of the cutting and conveying functions into two different processes.

2019

Every contractor is familiar with the following situation: To increase acreage output while maintaining high chop quality, more engine power is suddenly required. In 2019, KRONE developed the innovative XtraPower solution for such situations. Contractors can book 50 or 100 hp of additional engine power in just a few minutes via the new E-Solutions Shop. The additional power is activated online on the registered machine immediately after purchase and the operator can activate it as required. The driver only uses XtraPower when he really needs the additional power. If the harvesting conditions are such that no additional engine power is required, the driver selects the ‘Pause’ option directly in the operating terminal; and the machine immediately resets itself fully automatically to its original engine power.

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)