Krone Multibale opens expansion opportunity

A baler that offers multiple options on bale size and density as well as increased capacity has had a significant impact for a Cambridgeshire farmer who has switched from a mixed arable enterprise to one that only grows grass.

The change in business strategy for David Rolls of Copy Yard Farm, Longstowe has freed up time to help build a straw baling contract business. The business is now able to produce and supply high quality hay, haylage and straw in a variety of bale sizes to equestrian and livestock enterprises within 20 mile radius of the farm.

Mr Rolls is a second generation tenant farmer on 300 acres of the Longstowe Hall Estate. Under his father’s tenure the heavy boulder clay farm supported continuous wheat, but when David took over the reins in 2001 he changed to a mixed arable cropping rotation including hemp. After introducing 150 acres of grass to the rotation to help clear up blackgrass, the arable enterprise effectively became uneconomical so the rest of the farm has now also been put down to grass.

Historically Mr Rolls ran a Welger baler with a flat eight bale sledge for hay and straw on the 150 acres. At the same time he employed a local contractor to come in and make larger bales with a 80/90 New Holland.

“Our Welger was so slow and the New Holland was very heavy and difficult to move about. The bales it produced were also a challenge to stack because they were taller than they were wide,” he explains. “We used to make hay and then re-bale it in the winter into conventional sizes, but this was dirty and hard work.”

According to Mr Rolls this was a turning point for the company. An advert in the agricultural press at the time was selling a Krone MultiBale and so he went to see it in the local dealer’s yard and then went to see one working at Plumpton Racecourse.

In 2016 Mr Rolls bought a one year old 870 HDP MultiBale on finance and it was at this point he decided to then put the whole farm down to grass.

“Growing less cereals became unviable and we were using contractors anyway at the time to do the cereal harvest as we were concentrating on the grass business.”

The 870 HDP MultiBale was the last piece of equipment needed to have all the kit necessary for the business to go into full grass production. The Krone MultiBale has five strings; two to hold the multi pack and three to hold the main bale. For all the double knotters there is an air compressor which is used to clean the string. Leaf sprung suspension and double axles make the Krone baler a comfortable and safer ride for the operator.

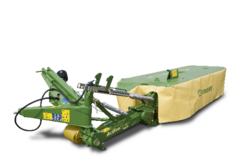

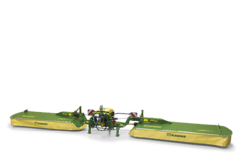

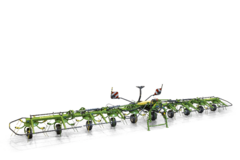

The machinery portfolio includes a 3.6m mower, a 10.2m tedder and a Lely 7.15m rake. The rake was replaced last season for a Krone 9.3m. The Welger round baler with fixed 4ft chamber has been kept for a small number of clients who still prefer round bales.

The machinery portfolio includes a 3.6m mower, a 10.2m tedder and a Lely 7.15m rake. The rake was replaced last season for a Krone 9.3m. The Welger round baler with fixed 4ft chamber has been kept for a small number of clients who still prefer round bales.

With more capacity and an expanding business Mr Rolls decded to develop his own hay and straw contracting enterprise.

“Last year we produced 15000 large straw bales (120 x 90) and about 3000 smaller straw bales (80 x 70),” says Mr Rolls.

“Rather than invest in a new baler we hired in a Massey 2270 XD. As it happened, we had huge problems with shear bolts breaking on the baler and up to 16.5 man hours were wasted changing them in the season. It was something like 100 shear bolts had to be changed in total

“The advantage of Krone’s MultiBale is that it doesn’t use shear bolts, instead it runs with a clutch. Not being able to rely on the Massey we have recently taken possession of a Krone 1290 HDP II,” he says.

Having the small Krone baler has given Mr Rolls the confidence that the 1290 baler will work as well as its smaller cousin and be supported with good back-up.

Being able to produce larger bales means he has increased capacity, allowing him to make haylage at the optimum timing when quality is at its best. He can also finish earlier in the season now and be more selective on when and how much he cuts. Bigger bales are easier to move off the field too, which creates less compaction on the land.

“When we had flat eights it would take an hour to unload compared to only 10 minutes or less with the larger bales,” explains Mr Rolls. “It’s also quicker to get them in the shed and out again. When stacked the large bales are more stable and in transit too.”

Mr Rolls applies acid to about 20% of his baled grass which means he can operate even in less than favourable conditions. He uses the fully automatic Balers Choice acid applicator from the Profitable Farming Company, which fits on the back of the baler where a metering unit measures the exact amount of acid applied per tonne.

“If you’re going to run a big baler doing hay you must have one of these systems onboard. The metering unit can also be used to accurately apply additive for haylage.”

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)