OptiGrass for the Perfect Cut

KRONE is setting new standards for forage quality and throughput in the professional loading and forage transport wagon segment with the new OptiGrass cutting unit.

Spelle, September 2023: The KRONE OptiGrass concept used in the new RX and ZX short cut loading wagons enables extremely neat, homogeneous and uniform forage quality. This is achieved by a precise cutting process with the option for selecting theoretical cutting lengths of 28 or 37 mm. Thanks to technologies optimally coordinated with each other, perfectly conditioned, top-quality forage is ensured from the first to the last stalk.

Uniform crop flow

The uncontrolled EasyFlow pick-up, 2.12 m wide, ensures neat pick-up and transfer of the forage to the cutting rotor and a very uniform crop flow. Thanks to the hydraulic drive, the tine speed can be adapted to the throughput so that the material is fed to the cutting rotor uniformly. That not only improves forage quality, but also lowers fuel consumption.

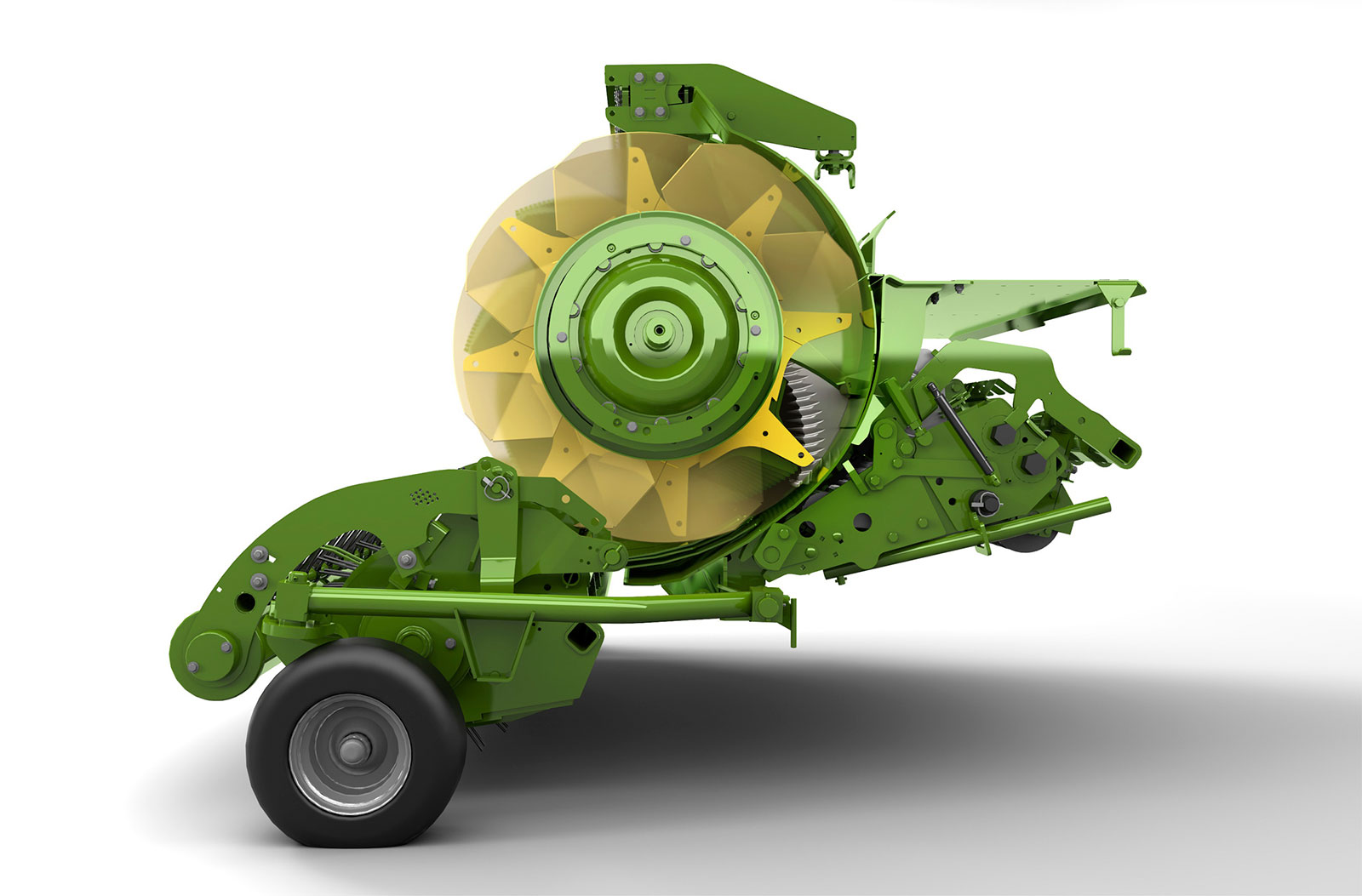

Integral rotor with SplitCut

The core element of the new RX and ZX short cut loading wagons is the cutting unit. Its integral rotor ensures consistent distribution of crops along the entire cutting width. The blades arranged on the side of the conveyor holding surfaces produce a perfect shear cut under all conditions with no mashing – thereby not only reducing the amount of force required, but also handling the forage gently. The conveyor holding surfaces, which are 17 or 22 mm wide depending on the cutting unit, are made of highly-tempered case hardening steel that is extremely rugged and durable. On the sides of the integral rotor there are augers approx. 22 cm wide that actively convey crops towards the centre of the rotor and form perfect forage packages for a precise cut. This unique technology in interaction with the KRONE SplitCut system ensures that even in the edge area of the rotor no stalks reach the loading area without being cut. To ensure this, the crop flow on the outermost blade is split up and conveyed back to the front by means of clearing tines. Crop deflector sheets guide the material centred to the rotor, where it is cut. This ensures exact cutting quality along the entire width!

High-Precision Cutting Technology

The new high-performance drill cutting unit is available in two variants: The "OptiGrass 37" with 40 blades provides theoretical cutting lengths of up to 37 mm. The "OptiGrass 28" with 54 blades is even able to achieve a theoretical cutting length of up to 28 mm – ideal for harvesting moist silage! The OptiGrass cutting unit uses an exact shear cut to provide the optimum cutting pattern as well as incomparable comfort. Thanks to the integral rotor concept, a 25% shorter cut is achieved for example with the ZX loading and forage transport wagon compared to the predecessor model with only six additional blades.

The Perfect Drive Concept

The wide rotor with internal planetary gearbox in combination with the PowerBelt drive concept ensures maximum throughput. Thanks to the cushioning of peak loads, this drive concept features quiet running and especially low wear. This too is available only from KRONE: The two pulleys can be quickly and easily exchanged to adapt the rotational speed of the rotor to the relevant harvesting conditions. In this way the rotor pockets are always optimally filled with forage and by means of pre-compression ensure the best possible cutting quality.

Conclusion: The unique technology of the OptiGrass cutting units, combined with sophisticated technical features, ensures a level of forage quality never before attained in the professional segment together with maximum throughput for RX and ZX short cut loading wagons.

Press Contact:

Markus Steinwendner

Head of Marketing KRONE Agriculture

+49 5977 935 188 20

markus.steinwendner@krone.de

www.krone-agriculture.com

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

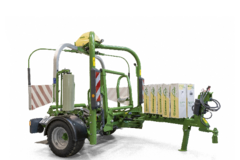

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)