5 years of mykrone.green

mykrone.green, the KRONE customer portal, is celebrating its 5-year anniversary, which has been met with great interest…

KRONE SILOKING smaXtec Best Practise Project

Small CO2 footprint for the milk

Krone, Siloking and smaXtec demonstrate in a joint project how milk production can be optimised using innovative…

Krone Dealer Focus - Moore Farm Services

Moore Farm Services Ltd based on the Nottinghamshire/South Yorkshire boarder was founded by husband-and-wife team David and Liz Moore in 2010. They…

Krone Group focuses on stable future plans

The turnover of the globally active Krone Group declined in the completed financial year 2023/2024 from 3.2 billion euros to just under 2.4 billion…

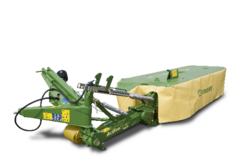

Krone Butterfly mower breaks the 1000 mark

Krone has written another page in its success story with the EasyCut B 950 Collect, having produced a thousand units.

Jürgen Hölscher new member of the Supervisory Board of the Krone Group

Expanding expertise for stability and sustainable growth

Krone UK look forward to welcoming Lamma visitors to Hall 19, Stand 530 where they can see the latest technologies and speak to the team, who can…

G Engineering Ltd. Becomes Krone dealer for Suffolk

Krone UK is proud to announce G Engineering Ltd. have been appointed as Krone dealer for Suffolk, where they will offer a full portfolio of Krone…

Cycling farmer and forager to cover 1000 miles across Britain for charity

Somerset farmer, Nick Bragg, of Frogmary Green Farm, is embarking on an extraordinary cycling challenge alongside a Krone BiG X forager, to raise…

Prevent silage contamination with simple machinery adjustments

Machinery adjustments should be considered by farmers and contractors this spring, to prevent silage contamination from soil due to the wet conditions…

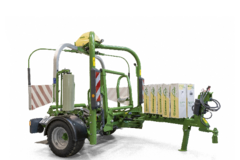

The KRONE warranty extension

When you buy a new KRONE mower, tedder or rake*, you can now secure a free warranty extension for one year per machine…

Krone’s SmartBale app wins LAMMA Digital Innovation Award

Krone UK has been awarded LAMMA’s prestigious Digital Innovation Award for its telematics SmartBale app.

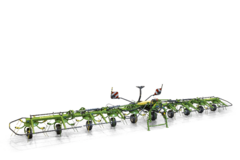

Traction 5-2023: Swadro TC 1570

KRONE erweitert seine Vierkreiselfamilie um ein neues Spitzenmodell, das ganz klar auf professionelle Betriebe und Lohnunternehmen abzielt. Beim…

Thorough winter maintenance key to extending forage machinery life span

As busy forage harvest seasons are left behind, it is time for farms to turn their attention to winter servicing, to extend the life of machinery, and…

High output grassland equipment from Krone at AgriScot

Krone UK will showcase the BiG X 1180 self-propelled forage harvester, the latest RX 370 forage wagon and Vendro 1120 C rotary rake at AgriScot 2023.

Swadro TC 2000 – Upgrade for the world’s largest rake

Spelle, September 2023. First introduced in 2009, the Swadro 2000 with its 19m maximum wingspan is undisputedly the world’s largest centre delivery…

Swadro TC 1250 – A Big Plus for Perfect Swathing

Spelle, September 2023: As a four-rotor rake with a variable working width from 9.80 to 12.50 metres, the Swadro TC 1250 has already proven to be an…

Efficient Mowing with Regard for Wildlife

Spelle and Alpen, September 2023: KRONE and Lemken combine their commitment to achieve the highest possible acreage output and ideal forage quality in…

Smart Implements: Everything is Controlled Automatically

Spelle and Alpen, September 2023: The process unit (VTE) of KRONE and Lemken presented under the name "Combined Powers" combines an autonomous towing…

Spelle and Alpen, September 2023: With the new transport solution from KRONE and Lemken, in the future it will be easy to hitch an autonomous process…

KRONE SmartBale app optimises bale logistics

Spelle, September 2023: Experience of recent years has demonstrated the need to make even more efficient use of small harvest windows due to weather…

Spelle, September 2023: The KRONE OptiGrass concept used in the new RX and ZX short cut loading wagons enables extremely neat, homogeneous and uniform…

The KRONE blade sharpener on BiG X forage harvesters scoops a DLG Silver Medal

Spelle, September 2023. The novel blade sharpener from KRONE stands out for 2200 grinding cycles without requiring manual resetting of the grinding…

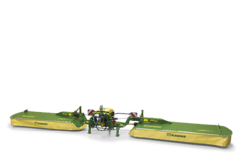

EasyCut B 880 CV/CR (Collect) and B 1050 CV (Collect)

With the EasyCut B 880 CV/CR (Collect) and B 1050 CV (Collect), KRONE presents two new and highly efficient Butterfly combinations. They come with…

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)